Your Products have been synced, click here to refresh

Your Products have been synced, click here to refresh

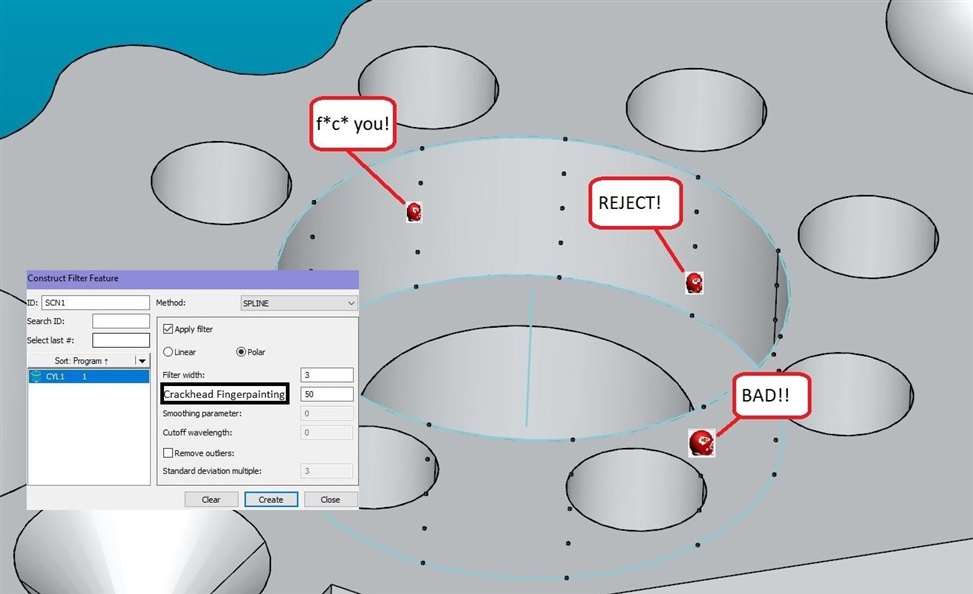

AMPLITUDE ERROR :scream;:scream;:scream;:scream;

What sort of filter do I need to apply to a scan to remove the “crotchety old” points?

That's the Joe Biden filter. He just sniffs them out.

A-machine-insp

bfire85

KIRBSTER269

I set the Hunter Biden Filter to 50 and the points are still there!!!:scream;

{"data-align":"none","data-size":"large","data-attachmentid":508055}

| © 2024 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |