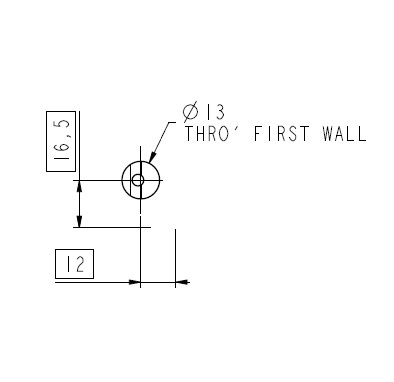

To my knowledge the ISO specification used being ISO 2768-m does not specify a true position to use for boxed dimensions with no positional tolerance, this is usually illustrated on the drawing in a tolerance frame around the hole call out? I'm looking to reply with words to that effect, am I right to say this?

I've checked the standard and I can't see anything on this, any advice would be greatly appreciated