I haven't used legacy before and need help on how to measure/report these composite true positions using it.

Datum A is a surface

Datum B is a bore

Datum C is a bore

I have my alignment set up to ABC.

In TP#1 how do I ignore C to get the AB alignment?

and how do I get just B for the composite?

In TP#2 How do I get the composite with no datums?

Can Legacy do MMC bonus or MMB datum shifts?

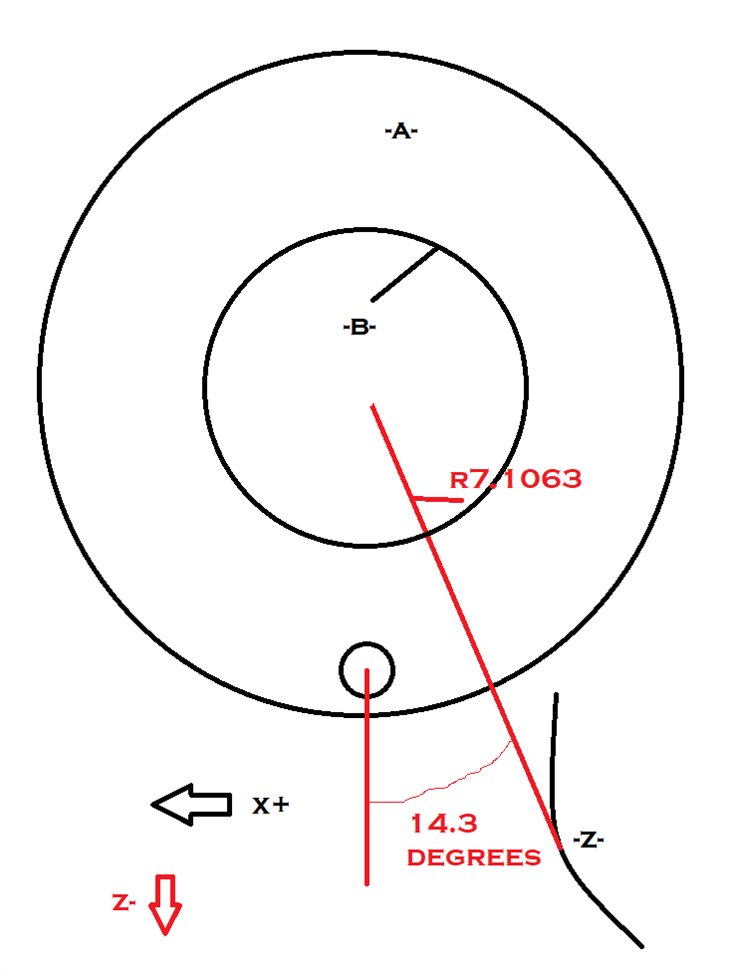

TP #1:

{"data-align":"none","data-size":"medium","data-tempid":"temp_22355_1648740249085_596"}

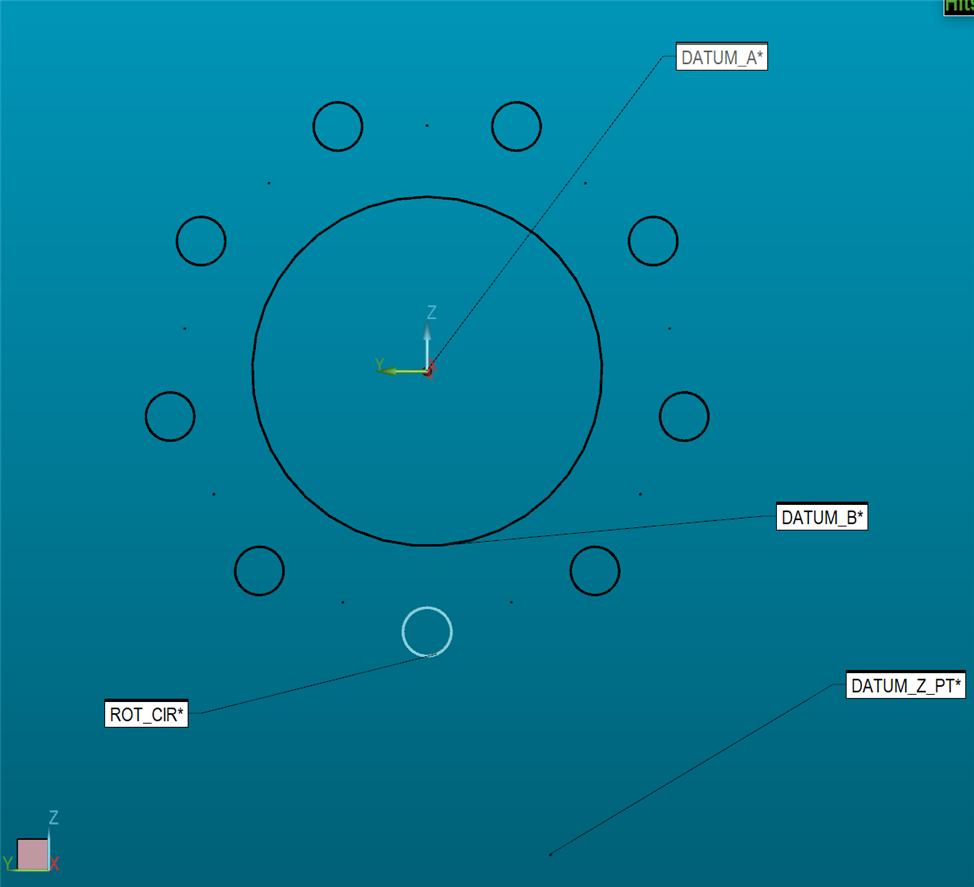

TP #2:

{"data-align":"none","data-size":"medium","data-tempid":"temp_22356_1648740215078_727"}

{"data-align":"none","data-size":"medium","data-tempid":"temp_22356_1648740215078_727"}

updated graphic

updated graphic