I greet you all, colleagues.

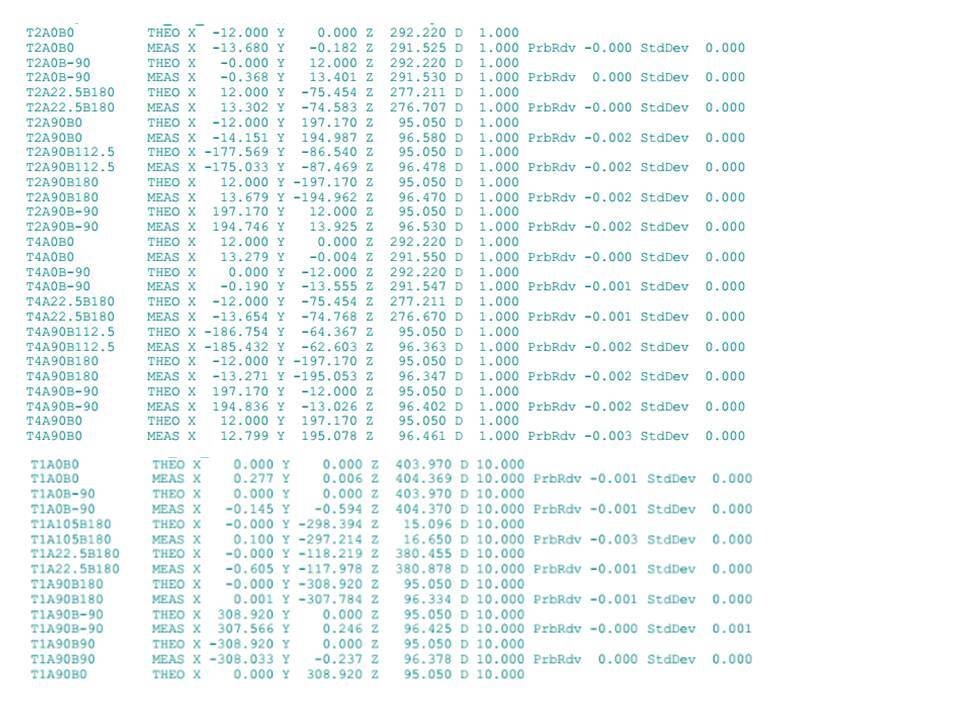

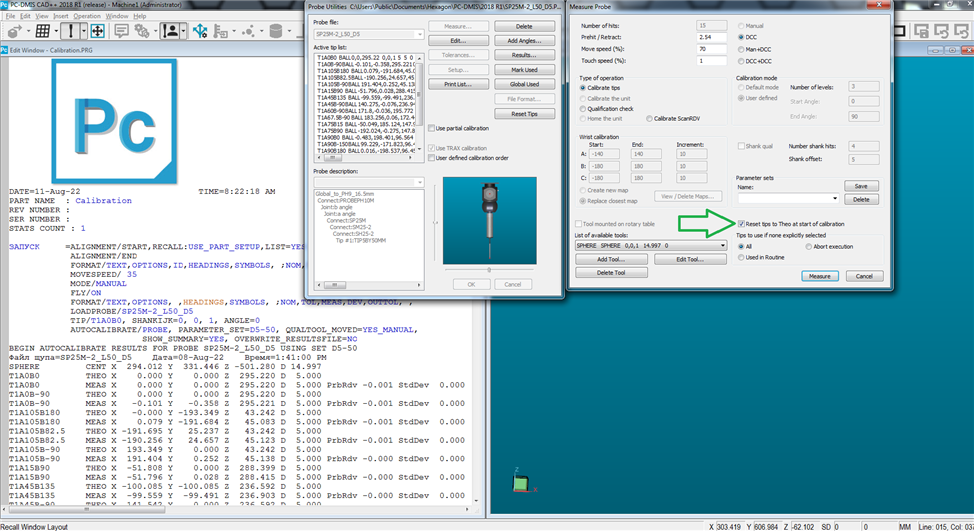

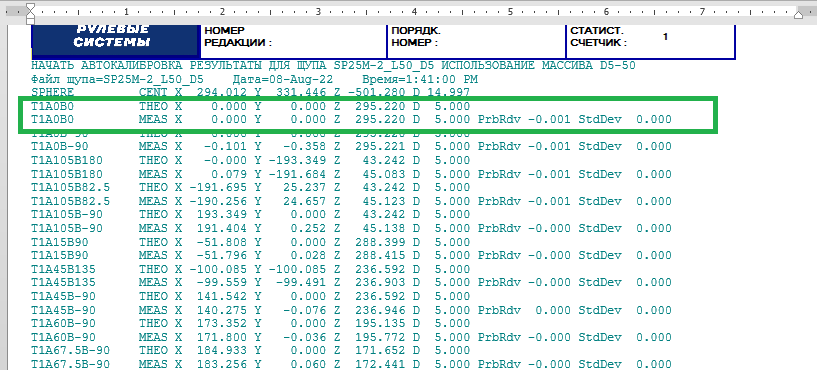

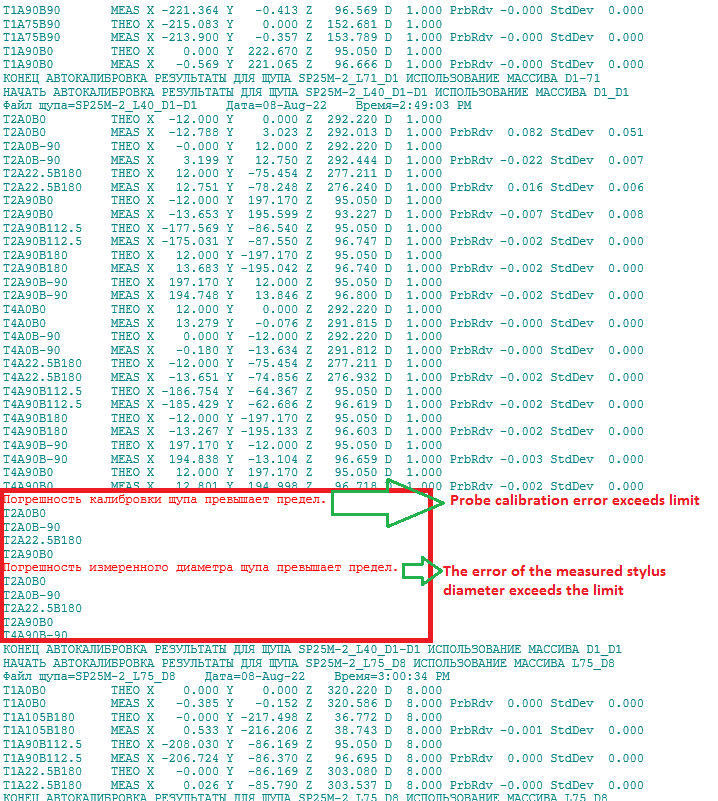

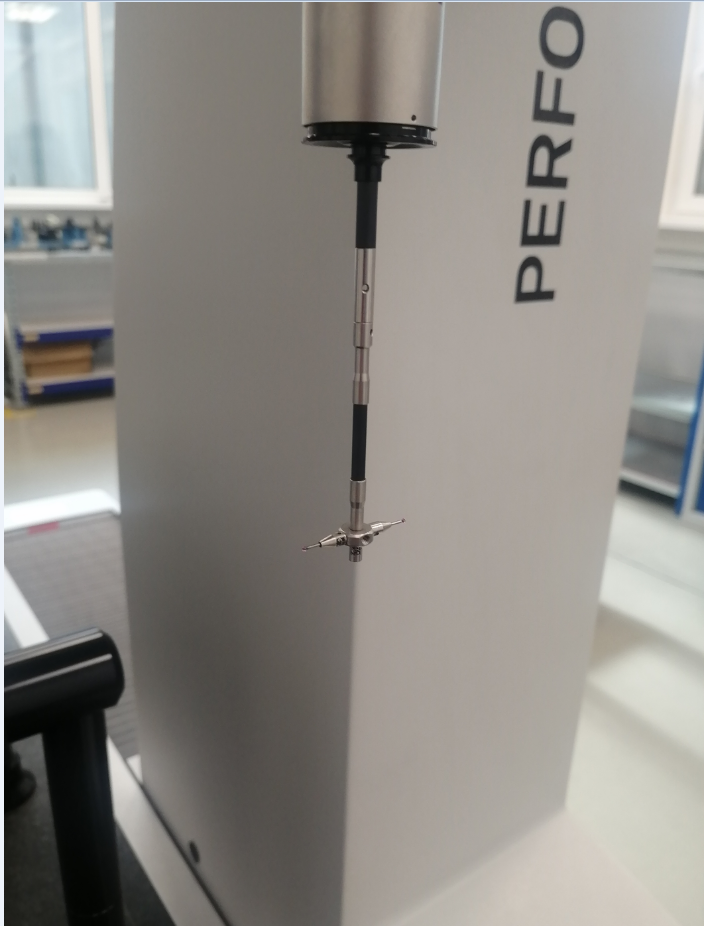

I have a small problem that tends to come and go when calibrating angles. I work with many styli and use a 9-slot magazine for this. Each stylus has about 10 different angle positions. When I did the calibration, two angles on different probes were out of tolerance. One probe has a CM25-2 probe and the other CM25-3. And at the same time, PSDMIS accepts the calibration result without asking the operator. The next day I did a similar calibration and the result was OK.And always out-of-tolerance angles equal to A90 or more than A90 It is very strange . I have been working in this mode for 3 years and there were no such problems. And this year it started. I check the probes visually and do the cleaning before each calibration the same way always. What could be the problem ?