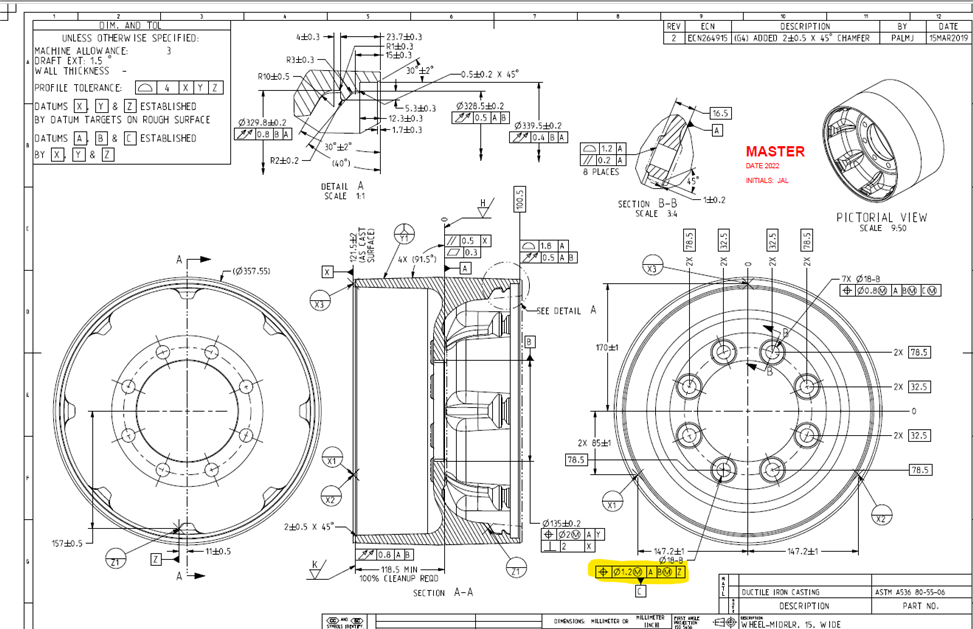

How would I include Datum -Z- in the alignment highlighted?

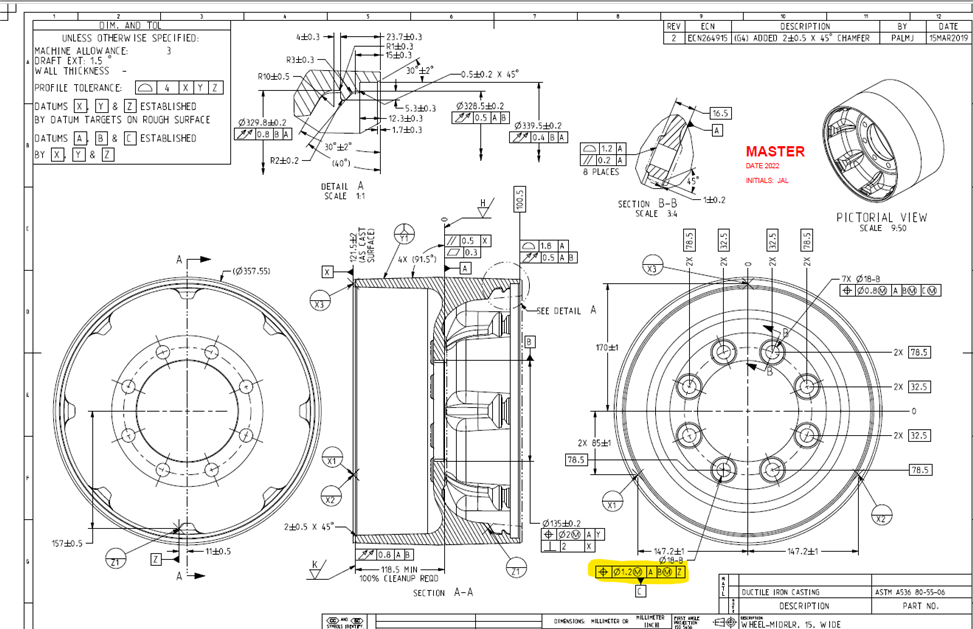

How would I include Datum -Z- in the alignment highlighted?

Your Products have been synced, click here to refresh

Your Products have been synced, click here to refresh

How would I include Datum -Z- in the alignment highlighted?

How would I include Datum -Z- in the alignment highlighted?

| © 2024 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |