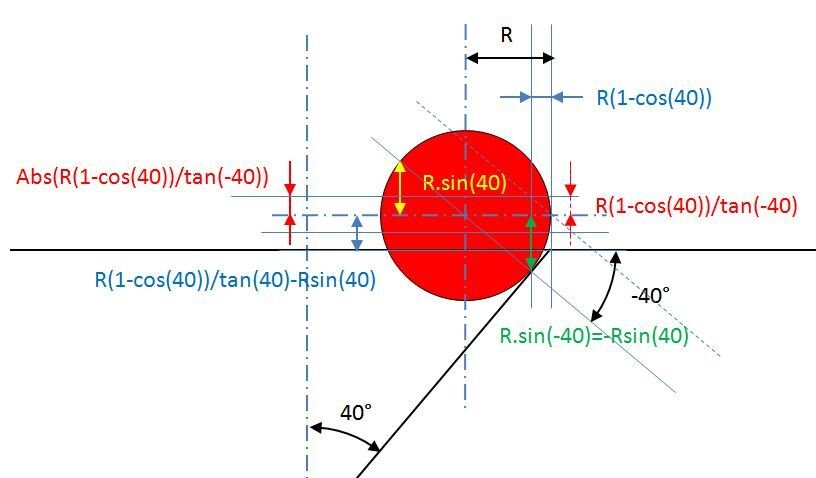

Some of our parts have port features which include a 40° included angle lead in chamfer. This is dimensioned as an angle with either a diameter or depth. These are machined using form tools previously inspected. These chamfers are typically left for manual inspection due to the complications of Cmm measurement. In trying to lighten their load I experimented with a few different ways of doing this with a probe. The below method takes advantage of cosine error and correlates within .001" to a gage ball/ height gage setup. I use 3 sample hits on the entry surface and 6 hits for the diameter. Aggressive benching or chatter can have a large influence on the results. The angle is not measured and must be known beforehand. The actual angle is supplied via "V_IA".

This approach isn't for everyone but if it suits your application...

$$ NO,

* derived Chamfer Diameter utilizing cosine error

* V_IA = included angle

* V_HA= half included angle

* V_TR= tip radius

* V_MD = hole measurement DEPTH (yields negative value to measure above surface)

* V_CD = contact depth for reference (positive values are below surface)

*

ASSIGN/V_IA=40

ASSIGN/V_HA=DEG2RAD(V_IA/2)

ASSIGN/V_TR=PROBEDATA("DIAM")/2

ASSIGN/V_MD=(V_TR - COS(V_HA) * V_TR) / TAN(V_HA) - SIN(V_HA) * V_TR[/SIZE][/B]

ASSIGN/V_CD=SIN(V_HA)*V_TR + V_MD

CIR1 =FEAT/CONTACT/CIRCLE/DEFAULT,CARTESIAN,IN,LEAST_SQR

THEO/<0,0,0>,<0,0,1>,0.665

ACTL/<0,0,0>,<0,0,1>,0.665

TARG/<0,0,0>,<0,0,1>

START ANG=0,END ANG=360

ANGLE VEC=<1,0,0>

DIRECTION=CCW

USE_PIN=NO

REPORT VEC=<0,0,1>

SHOW FEATURE PARAMETERS=NO

SHOW CONTACT PARAMETERS=YES

NUMHITS=6,DEPTH=V_MD,PITCH=0

SAMPLE METHOD=SAMPLE_HITS

SAMPLE HITS=3,SPACER=0.1

AVOIDANCE MOVE=BOTH,DISTANCE=0.25

FIND HOLE=DISABLED,ONERROR=NO,READ POS=NO

SHOW HITS=NO