Hello all.

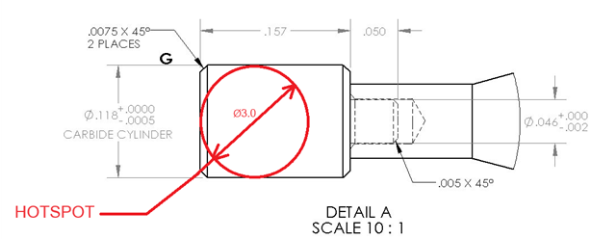

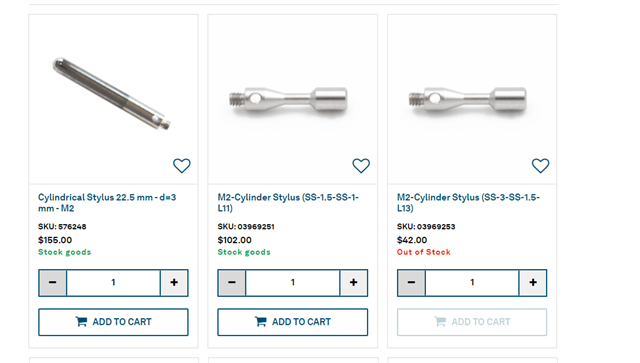

I have been having an issue with a custom cylinder probe for a while now. A forum friend of mine has previously helped me, but I don't want to bother him yet AGAIN. The cylinder probe is a 3mm (dia) x 13mm (length from tip to thread shoulder) with a 20mm extension. I had to tear the probe down a couple of days ago because another job came up. Well, I'm back on the job that needs that probe so I built it again. When I calibrated it this time, it comes up w/ the error "measured probe diameter exceeds limits". The 3mm cylinder checks anywhere From 3.290mm to 3.330mm. For some reason it's NOT calibrating around the equator of the sphere. In all honesty, I guess it doesn't really matter for THIS job, since I only need the probe to check in the Z direction. But what IF I ever need this probe to check diameters? I'm screwed. I contacted Hexagon back in May of last year when we first bought the probe because it wasn't in the drop down menu. I was on the phone for 2 or 3 days with the guy, and he had control of my computer. NEVER could get the probe to read diameters correctly. I finally gave up because I only needed the Z direction. Here is the usrprobe file. Can anybody PLEASE help me? Thank you in advance.

ITEM:TIP3BY13MM_CYL_PART_268 M2

EffectiveWorkingLength 13.0

begintip

ribcount 10

color 80 80 80

cylinder 0 0 0 0 0 -2.5 3

cone 0 0 -2.5 3 0 0 -5.5 2.0

color 80 80 80

cylinder 0 0 -5.5 0 0 -7.5 2.0

cone 0 0 -7.5 2.0 0 0 -9.0 3.0

cylinder 0 0 -9.0 0 0 -12.8 3.0

cone 0 0 -12.8 3.0 0 0 -13 2.8

sphere 0 0 -11.5 3.0

hotspot 0 0 -11.5 0 0 1 3.0 3.0 shank

endtip

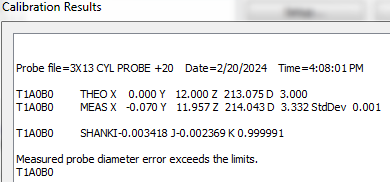

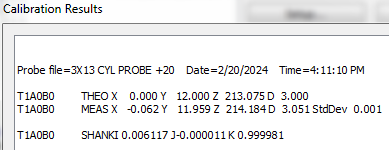

Probe file=3X13 CYL PROBE +20 Date=2/8/2024 Time=1:46:41 PM

T1A0B0 THEO X 0.000 Y 12.000 Z 213.075 D 3.000

T1A0B0 MEAS X -0.058 Y 11.961 Z 214.065 D 3.290 StdDev 0.002

Measured probe diameter error exceeds the limits.

T1A0B0