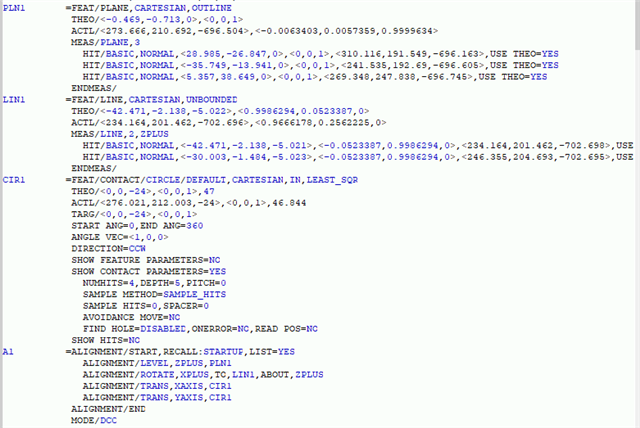

Hello, I'm programming on a new CMM and having issues with my manual alignments. I have been programming in offline mode and whenever I try to run my programs on the machine after I pick up my manual alignment I get this error message: ERROR CE ,S% ,TR_CE ,0x1400304d Position out of the machine stoke limit. Then after that message it sometimes says on _ blank axis, and I have had this happen on several different axis and not just one. Sometimes I may get a probe deflection error and I can usually sort it out if that happens but I cant figure out why my Hexagon Global CMM is giving me this error. I also attached a screenshot with my machine coordinates with this issue being the Z axis and my machines probe location in Z being way off. Could this be a pre-hit and retract issue? A setup or alignment issue? Thanks

Deleted one image

[edited by: Austin Lee at 4:10 PM (GMT -5) on Jul 9, 2024]