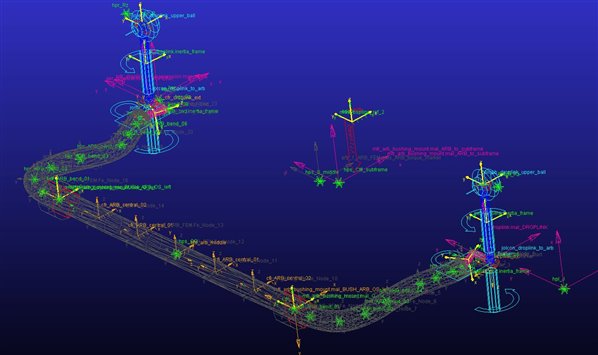

- simple method (torsional stiffness - for instance you could get torsional stiffness from NASTRAN and to use it in ADAMS);

- BEAM method

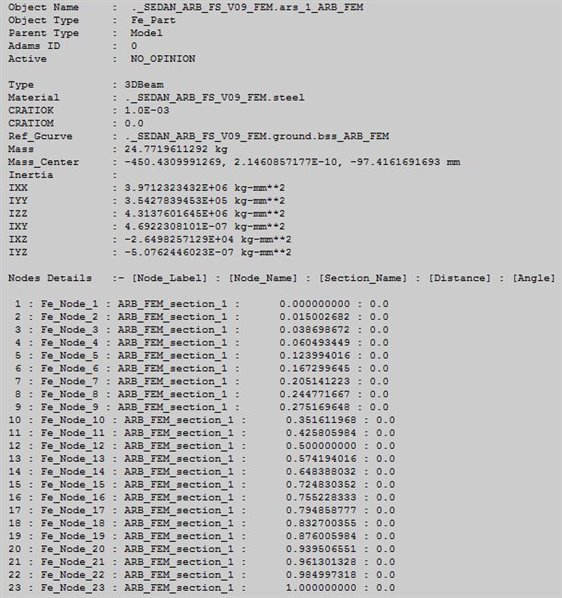

- FE method

- simple method (torsional stiffness - I calculated torsional stiffness in ANSIS (I got 602 [N*m/deg] of torsional stiffness);

- BEAM method (this method gave me 930.8 [N*m/deg]);

- FE method (this method gave me 930.6 [N*m/deg])

- test results: around 580 [N*m/deg]

Links (1)