Hi Everyone,

Apologies if this is a basic question I'm new to MSC Marc.

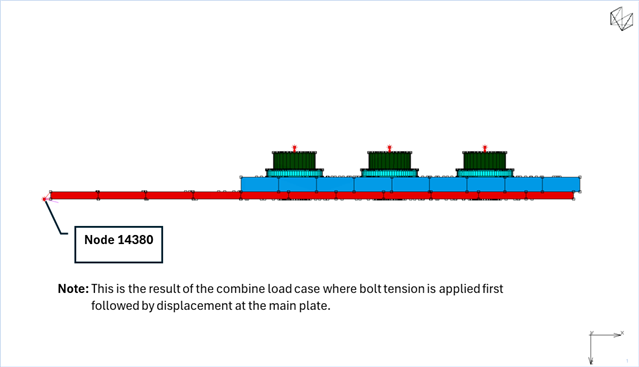

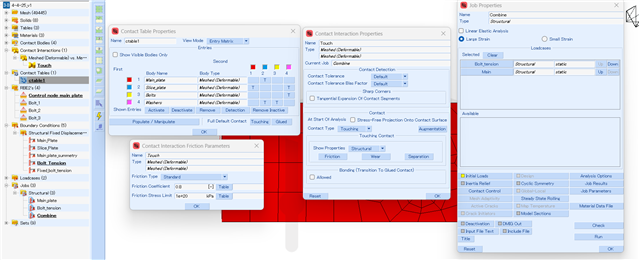

I've modeled a half-staggered bolted joint with symmetry along the vertical axis (perpendicular to loading). I applied symmetry boundary conditions at the splice plate end by restraining displacement in the X direction and rotation about Y and Z. However, after analysis, the model exhibits unexpected free movement in the Y and Z directions and terminates with error 3002.

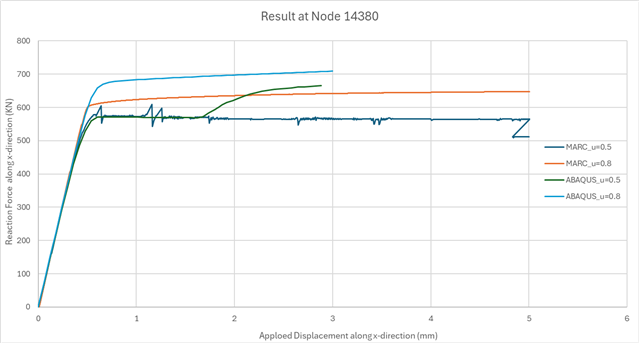

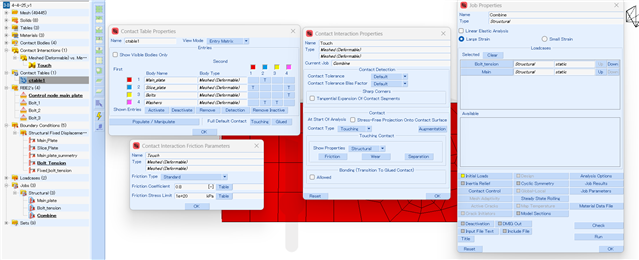

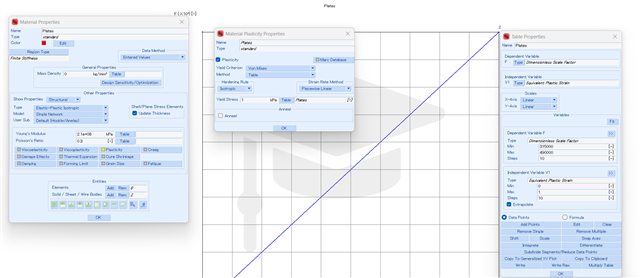

In a second attempt, I fully restrained all DOFs at the splice end. This time, the analysis completed successfully (3004) with no movement, but the results were not consistent with those from ABAQUS.

Additionally, I applied bolt pretension first, followed by a 5 mm displacement load in the X direction on the main plate. Surprisingly, the plate displaced by 10 mm in the final increment.

Despite several trials, I haven't been able to resolve these issues. I'd appreciate any suggestions. I'm attaching a comparison graph of results from both Marc and ABAQUS under identical settings.

Thank you in advance!