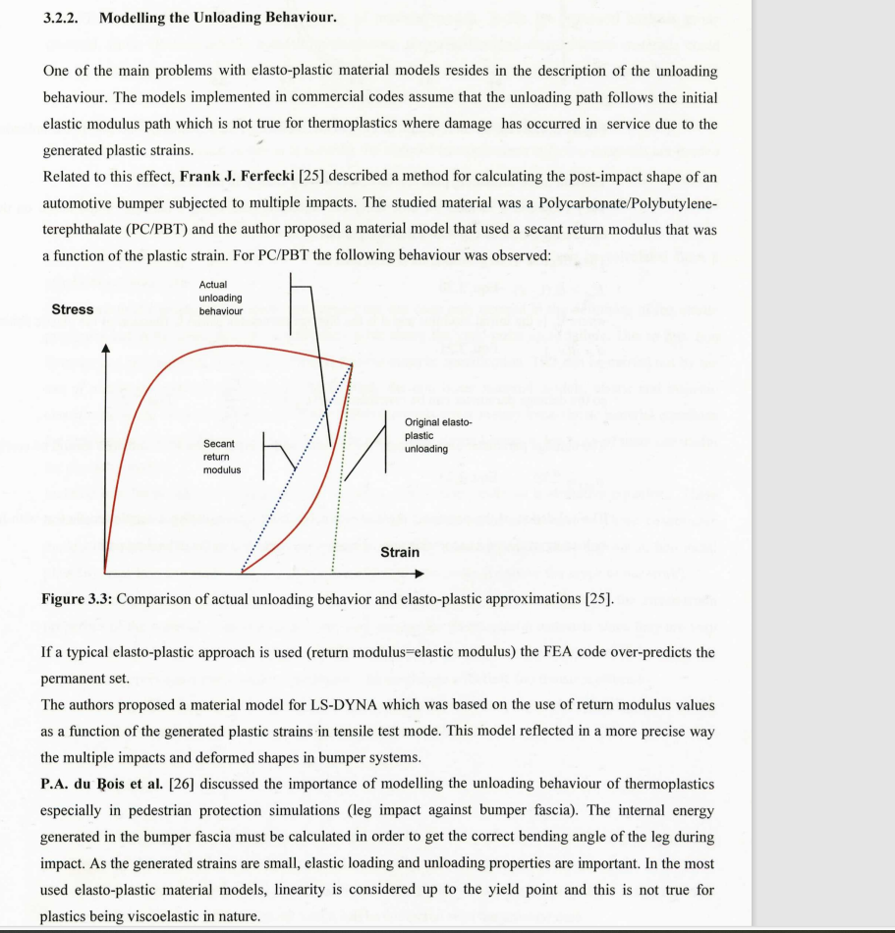

When loading thermoplastic materials based on an elastic-plastic material model up to the plastic range, unloading results in a plastic (permanent) deformation. The deformation is usually overestimated, since the recovery behavior is based solely on the Young’s modulus, as is common for metals. For thermoplastics, the elastic-plastic material model is a widely used practical approach because it is easy to use and input parameters such as stress-strain diagrams are available. However, viscoelastic or viscoplastic effects cannot be taken into account.

Are there possibilities to optimize the elastic-plastic material model with respect to the recovery behavior? For example, by choosing a specific yield criterion, flow method, or user subroutine?