Part Consolidation optimization starts with creating an initial design space, Access, interface and Clearance region for a number of parts in the assembly.

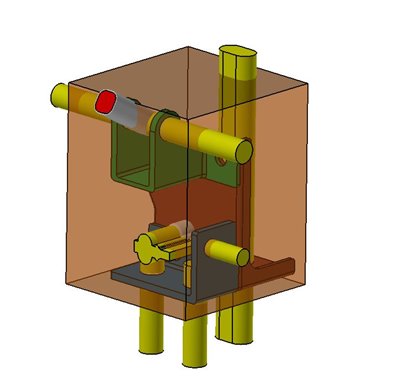

A demo model for part consolidation optimization using Apex Generative Design is demonstrated.

The Generative Design Configuration tool allows you to define all aspects of a generative design analysis from a single tool and creates the final design space for the optimization.

This Design Space includes all previously created Non-Design Spaces, Interfaces and Retained volumes.

Below topics to be discussed for a complete overview of the process.

• Introduction to MSC Apex Generative Design

• Usage of MSC Apex Generative Design

• Introduction to Part Consolidation Optimization

• Generation of Access, Clearance and Interface region

• Creating the generative design configuration

• Demo Example for part consolidation optimization and Results Discussion