Your Products have been synced, click here to refresh

Your Products have been synced, click here to refresh

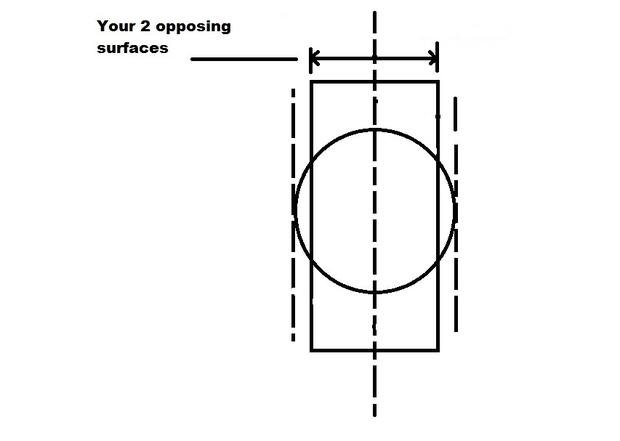

Ok. We have all seen this. A print with a centerline call out that really only controls size and not location. Think of this as solid block with a U shape cut thru it. The entire U shape is severely tipped to 1 side. We almost have a this wall condition on side. The U itself has perfect size and form. . We are getting push back from another dept saying according to the print it is good to go! There is a note saying all undefined geometry is controlled at +/- .010 on the print and we also use an internal control that states +/-.10 on all undefined dimensions. This dept has never heard of that document for some reason. So I would say the shape itself needs to be within .010 of the C/L. Can everyone out there quote a standard that talks about undefined symmetry ? Y14.5 has nothing ( and I didn't expect it to ) . The drawing isn't referencing any other specs and it is an internal drawing so this is more of a dept vs. dept P!$$!NG match. I would like to win this war with a MOAB !

| © 2024 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |