Your Products have been synced, click here to refresh

Your Products have been synced, click here to refresh

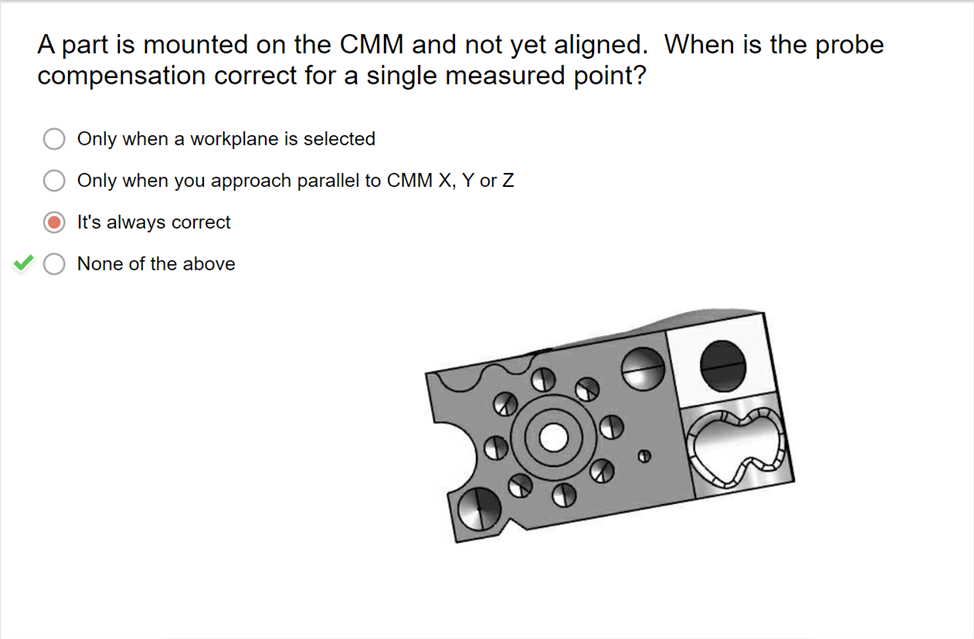

It will 'never' be correct to your part, unless you part is perfectly flat and square to the machine axis.... FOR SINGLE POINTS.

A plane will get the correct probe comp. A sphere will as well.

BUT, a line measured without an alignment will be comped to MACHINE plane, not part plane.

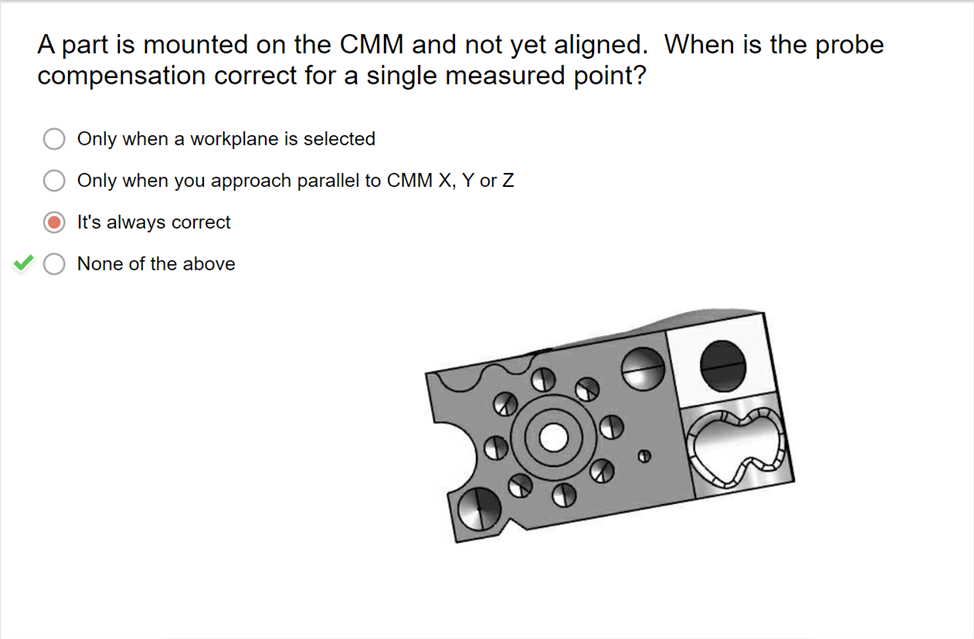

It will 'never' be correct to your part, unless you part is perfectly flat and square to the machine axis.... FOR SINGLE POINTS.

A plane will get the correct probe comp. A sphere will as well.

BUT, a line measured without an alignment will be comped to MACHINE plane, not part plane.

| © 2024 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |