Hello there!

I'm new in this forum and I hope I pick the right group for my question.

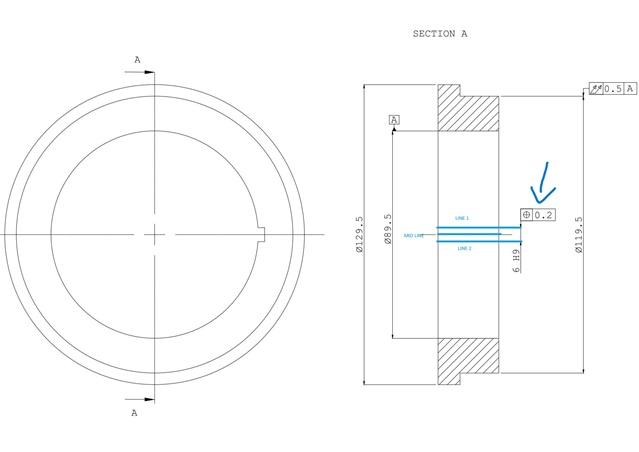

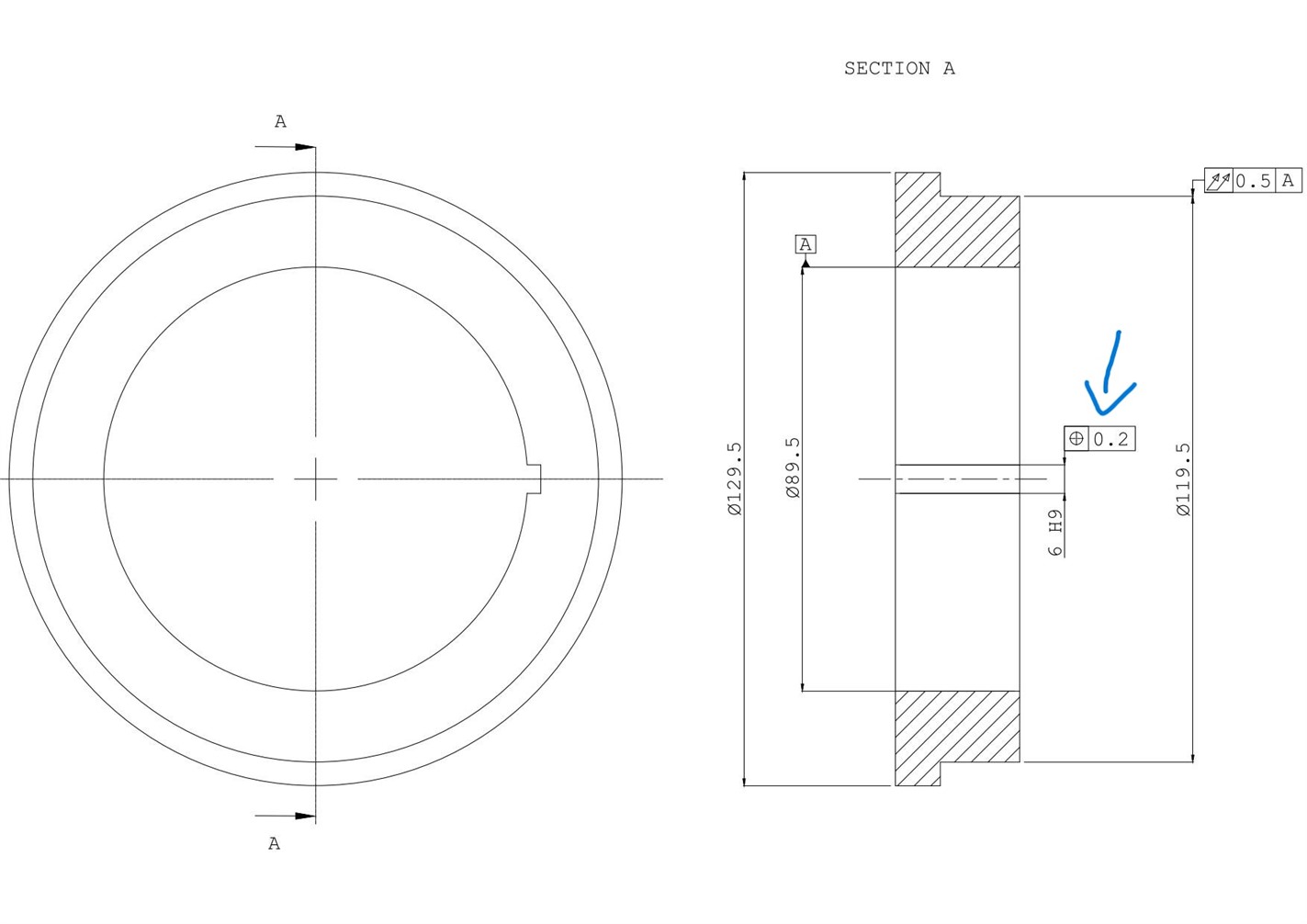

I have to check this tolerance:

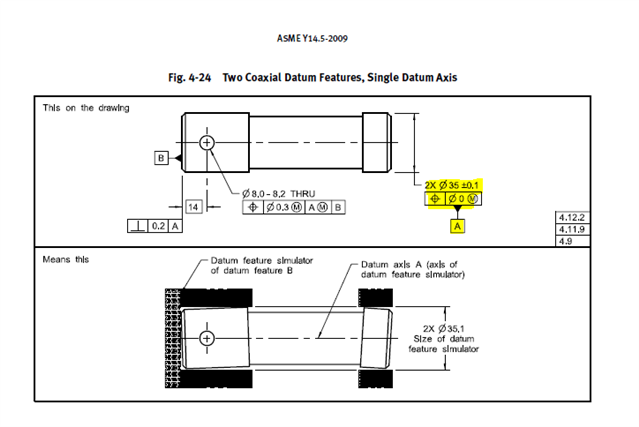

I tried a lot of times and I couldn't find a reliable code to check on this tolerance.

Any idea about the strategy?

Thanks in advance!