Im quite new here to the forum and this is my first official post.

I've been thinking quite alot about how to make the PC-DMIS program easier for operators and users who are not to educated in the program itself.

In my type of work area, I have around 12-15 people who are using the measurement machine.

And not everybody are well educated in the program so they can use it to find out the information they want to.

Also if a result is not correct and the report only says "from point A to point B is not correct" and to the other personel they dont know what to do.

And if im not around it's quite annoying cause I myself cant handle to much support via telephone, im much more useful behind a computer with the same parameters.

So I have a solution to discuss with the others and I want to throw around the ball.

The suggestion I want to bring is in text aswell as Im giving you some picture examples.

Suggestion:

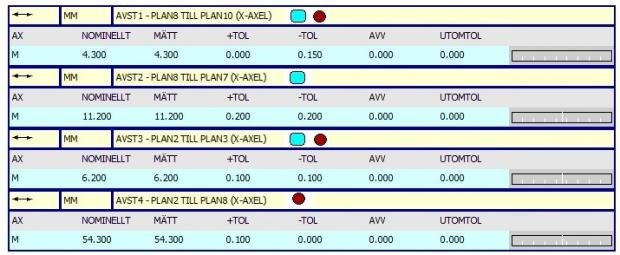

*Picture one*

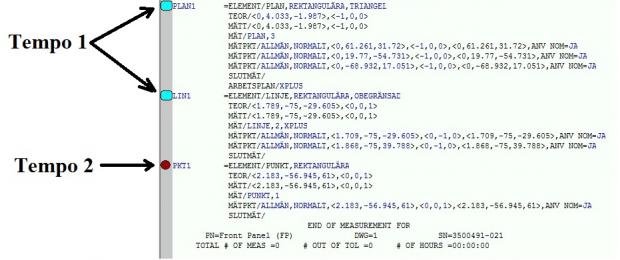

While programming a program I think there should be a possiblity to give every code a color (for example in this the Teal and Red dot - At The Moment in PC-DMIS they are used for Bookmark aswell as a breakpoint)

But lets forget what they are for the moment and join me in on this idee, instead the colors will represent a Tempo in the ongoing process of the NC Machines.

*Picture two*

So when I add to the result that "Plane8 to Plane10 (X-axel)" the Teal and the red dots are shown besides the result.

That's because "Plane8" in this case are from a Tempo 1 machining while "Plane10" is from the Tempo 2 machining.

In the result below the first one we have "Plane8" which we know is Temp 1 to "Plane7" In this case we havnt placed any color on "Plane7" but still the result will show a teal dot cause "Plane8" is defined as a Tempo 1 and we then can assume that "Plane7" is aswell.

This may be the weakness in this method, if a code is without a color for which tempo its from this form turns out just like coding without colors at all.

Even tho I think this is a potensial to help alot of programmers out there who have other personel who aint trained in programming the Machine and understands it to a potent way.

Attached Files

Picture one*

Picture two*