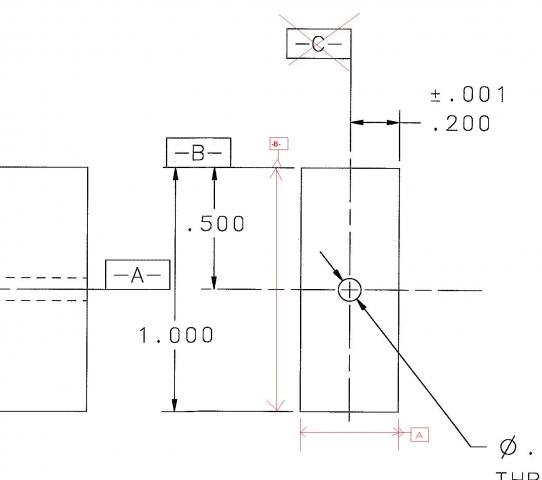

I keyed in gage points and read the vectors from the model. Part is out of tolerance (which I expected) by about .001, the profile being off center.

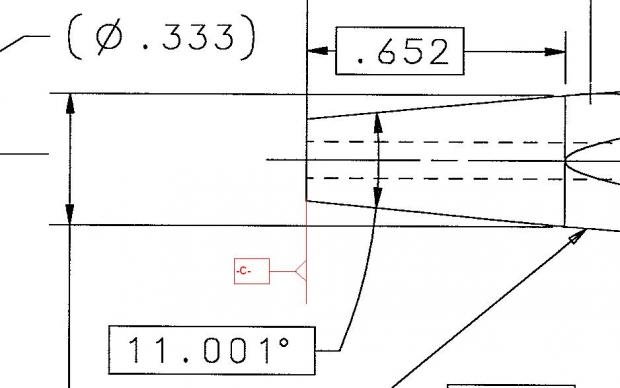

Next I added a linear TTP scan along the same section where I probed the gage points. The scan shows deviations up to .018!

What could I be doing wrong with my scan to get a result that differs so much from my keyed-in points?