Your Products have been synced, click here to refresh

Your Products have been synced, click here to refresh

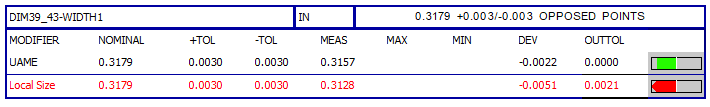

This should be a quick one for you pros. I have a distance between 2 planes. The max is in tolerance but the min is out. Since using the distance dimension button uses the average, its telling me the feature is in when its not. How do I write a variable for this?

you can directly report min max using

F10 -> Dimensions -> min max

WORKPLANE/ZPLUS PLN2 =FEAT/CONTACT/PLANE/DEFAULT,POLAR,OUTLINE,LEAST_SQR THEO/<4.2562,103.565,-0.0341>,<-0.0196617,0.0814898,0.9964802> ACTL/<4.2562,103.565,-0.0341>,<-0.0196617,0.0814898,0.9964802> TARG/<4.2562,103.565,-0.0341>,<-0.0196617,0.0814898,0.9964802> ANGLE VEC=<0.9998054,0,0.0197273>,RADIAL SHOW FEATURE PARAMETERS=NO SHOW CONTACT PARAMETERS=YES NUMHITS=4,NUMROWS=1 SPACER=6.066 AVOIDANCE MOVE=NO,DISTANCE=0.3937 SHOW HITS=NO PLN3 =FEAT/CONTACT/PLANE/DEFAULT,POLAR,OUTLINE,LEAST_SQR THEO/<2.8668,117.5603,0.45>,<0,0,1> ACTL/<2.8668,117.5603,0.45>,<0,0,1> TARG/<2.8668,117.5603,0.45>,<0,0,1> ANGLE VEC=<1,0,0>,RADIAL SHOW FEATURE PARAMETERS=NO SHOW CONTACT PARAMETERS=YES NUMHITS=4,NUMROWS=1 SPACER=6.066 AVOIDANCE MOVE=NO,DISTANCE=0.3937 SHOW HITS=NO DIM DIST9= 3D DISTANCE FROM PLANE PLN2 TO PLANE PLN3,SHORTEST=OFF,NO_RADIUS UNITS=IN,$ GRAPH=OFF TEXT=OFF MULT=10.00 OUTPUT=NONE AX NOMINAL +TOL -TOL MEAS DEV OUTTOL MAX MIN M 0.4841 0.0030 0.0030 0.4841 0.0000 0.0000 0.9784 0.0101 --#-- ASSIGN/VMAX=DIST9.M.MAX ASSIGN/VMIN=DIST9.M.MIN ASSIGN/NOM=.4841 FMAX =GENERIC/POINT,DEPENDENT,CARTESIAN,$ NOM/XYZ,<0,NOM,0>,$ MEAS/XYZ,<0,VMAX,0>,$ NOM/IJK,<0,0,1>,$ MEAS/IJK,<0,0,1> DIM LOC39= LOCATION OF POINT FMAX UNITS=IN ,$ GRAPH=OFF TEXT=OFF MULT=10.00 OUTPUT=BOTH HALF ANGLE=YES AX NOMINAL +TOL -TOL MEAS DEV OUTTOL MAX MIN Y 0.4841 0.0035 0.0035 0.9784 0.4943 0.4908 0.9784 0.9784 ----> END OF DIMENSION LOC39 FMIN =GENERIC/POINT,DEPENDENT,CARTESIAN,$ NOM/XYZ,<0,NOM,0>,$ MEAS/XYZ,<0,VMIN,0>,$ NOM/IJK,<0,0,1>,$ MEAS/IJK,<0,0,1> DIM LOC40= LOCATION OF POINT FMIN UNITS=IN ,$ GRAPH=OFF TEXT=OFF MULT=10.00 OUTPUT=BOTH HALF ANGLE=YES AX NOMINAL +TOL -TOL MEAS DEV OUTTOL MAX MIN Y 0.4841 0.0035 0.0035 0.0101 -0.4740 0.4705 0.0101 0.0101 <---- END OF DIMENSION LOC40

| © 2025 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |