last week i came across an issue in which first hole was mismarked during production.

The part was similar to attached image with two set of holes 1st set has 30 holes and 2nd has 59, in which 1st hole of both set are inline with each other.

to find the correct hole what I did is:

loaded the part on cmm table with one hole from 1st set at 6 o' clock position

created alignment by rotating the random hole from 1st set

added move points such that probe stops on top of corresponding hole of 2nd set

added operator comment to continue to inspect if probe is on top of hole

operator needs to stop program if it goes on top of material instead of hole

location is called for hole inspected

same is repeated for every hole

the one with least variation is our 1st hole.

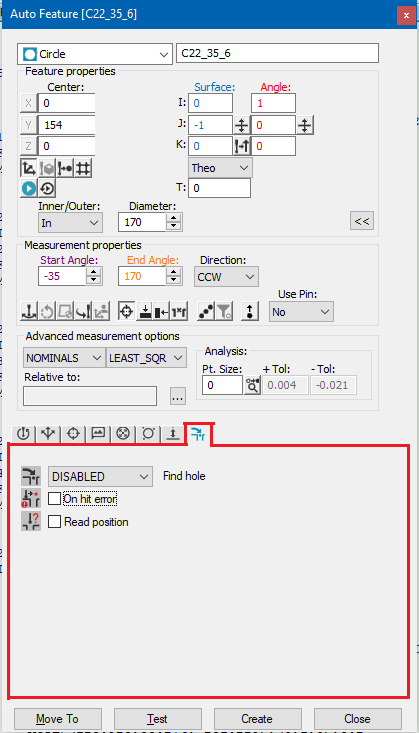

Is there a way to do this without involving the operator & avoiding probe deflection?

Please suggest if there is a better/quick way to do this..

Attached Files