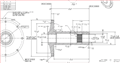

We've been asked to measure runout of a hub flange, and position of holes in the hub to A-B. A is a bore at one end of the hub, and B is, it looks like anyway, the pitch diameter of an internal spline. The pitch diameter is 47.625 mm and the spline is situated inside of a tube with a clearance diameter of 59 mm. We are using a global machine, and our soft ware is PCDMIS 2021. We don't think we can do it. We're going to ask engineering if we can use the minor diameter of the spline instead. We thought we'd run it by the big brains, just in case someone has a better idea.

Thanks.

Attached Files