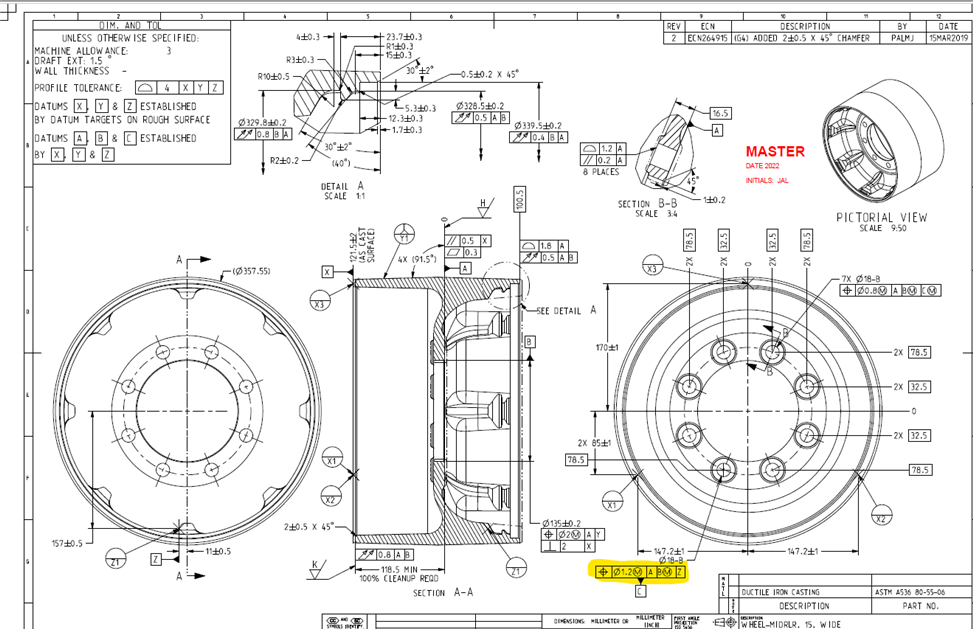

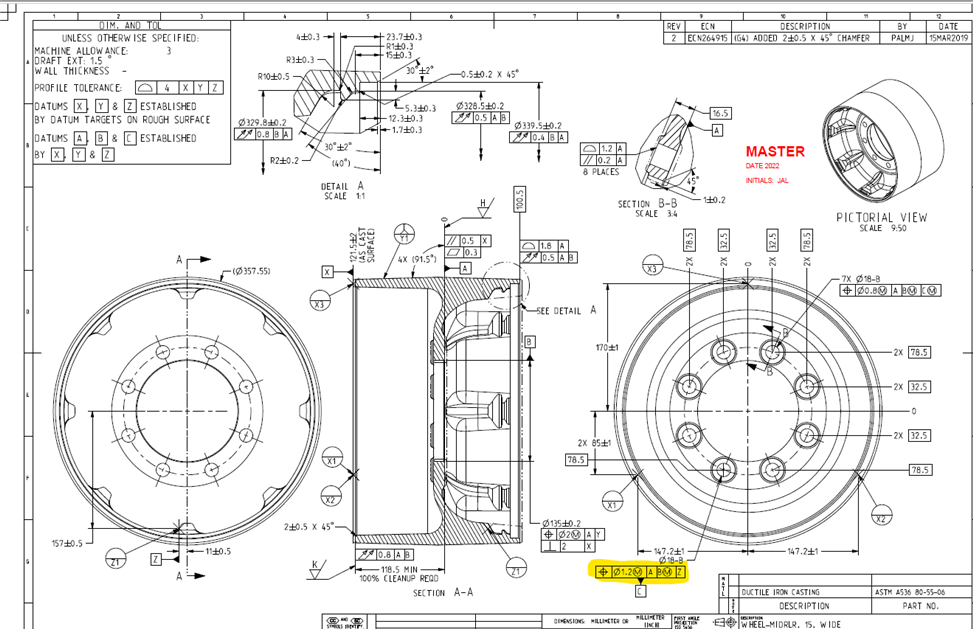

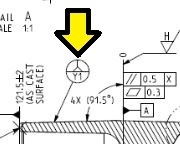

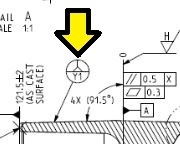

How would I create this alignment with (Z) in it? I can constrain all 6 degrees with (A) and (B), but i'm not sure how to include Point (Z)?

How would I create this alignment with (Z) in it? I can constrain all 6 degrees with (A) and (B), but i'm not sure how to include Point (Z)?

Your Products have been synced, click here to refresh

Your Products have been synced, click here to refresh

How would I create this alignment with (Z) in it? I can constrain all 6 degrees with (A) and (B), but i'm not sure how to include Point (Z)?

How would I create this alignment with (Z) in it? I can constrain all 6 degrees with (A) and (B), but i'm not sure how to include Point (Z)?

A and B do not appear to control all 6 DOF, A = Level/origin in Z axis (2 rotations/1origin), B = Origin X/Y (2origins), Z rotation about Z-axis(1 rotation)

Z does appear to need to be a constructed feature, it does not appear directly measurable with a singular point on CMM.

A and B do not appear to control all 6 DOF, A = Level/origin in Z axis (2 rotations/1origin), B = Origin X/Y (2origins), Z rotation about Z-axis(1 rotation)

Z does appear to need to be a constructed feature, it does not appear directly measurable with a singular point on CMM.

| © 2024 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |