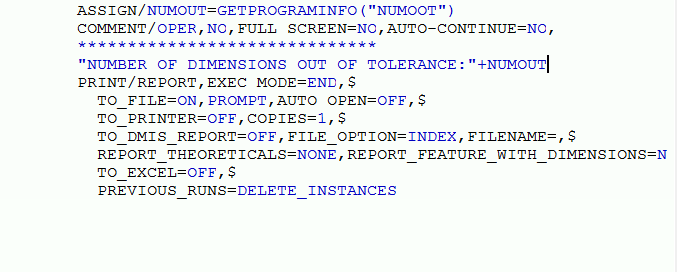

I have this code at the end of my programs for the operators to see if anything is out. If there is something out of tolerance then I don't want it to print(make a pdf). how would I write a variable for this to continue to the print/report if its zero out of tolerance.