Your Products have been synced, click here to refresh

Your Products have been synced, click here to refresh

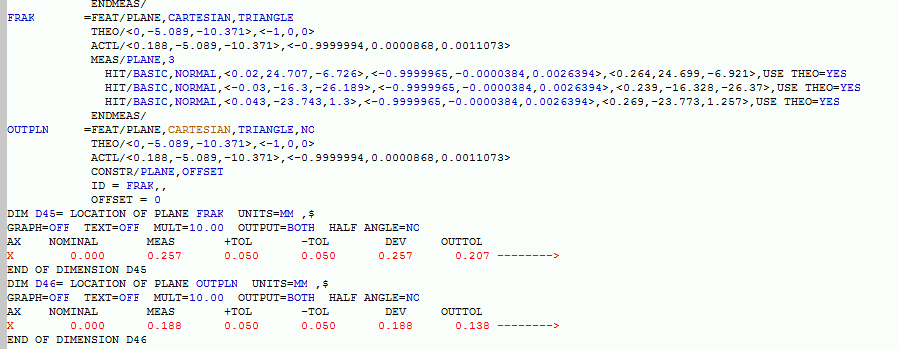

If you execute a routine partially, the resultant values of that execution are stored in the ACTL and MEAS results... which are then fed into dimensional outcomes.

Every time you execute a routine entirely, all of the ACTL and MEAS results will change based on the ACTUAL and MEASURED values of that component you just measured.

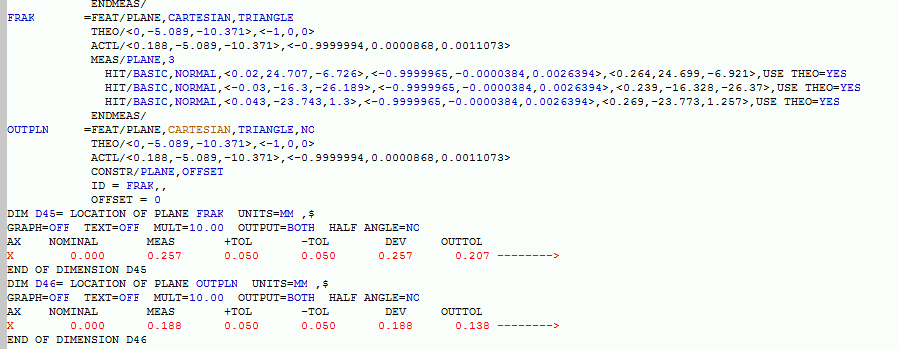

If you execute a routine partially, the resultant values of that execution are stored in the ACTL and MEAS results... which are then fed into dimensional outcomes.

Every time you execute a routine entirely, all of the ACTL and MEAS results will change based on the ACTUAL and MEASURED values of that component you just measured.

| © 2024 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |