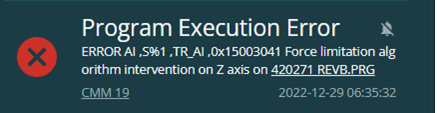

We were getting an error message on our machines that stated:

ERROR AI, S%1, TR_AI, 0x15003041 Force Limitation algorithm intervention on Z axis.

Come to find out it was a failure with the sprocket on the motor assembly breaking loose and needing replacing.

Just putting this out there to see if anyone else has had this problem as well.