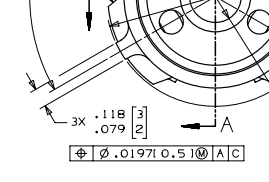

I am taking a point on each side of each fin to determine the .079-.118 thickness, then creating a midpoint between the two points. Then I used the midpoint to do the true position, but since it is a point, I can't take advantage of the MMC. I can probably have PC-DMIS put on the thickness on the report and then calculate bonus manually and subtract that from the true position on the report. But is there a way to have PC-DMIS do this so that it can take the thickness and then calculate bonus and apply it to true position?

I am taking a point on each side of each fin to determine the .079-.118 thickness, then creating a midpoint between the two points. Then I used the midpoint to do the true position, but since it is a point, I can't take advantage of the MMC. I can probably have PC-DMIS put on the thickness on the report and then calculate bonus manually and subtract that from the true position on the report. But is there a way to have PC-DMIS do this so that it can take the thickness and then calculate bonus and apply it to true position?

Your Products have been synced, click here to refresh