Your Products have been synced, click here to refresh

Your Products have been synced, click here to refresh

I just purposed to lock the rotation trying to explain the defects. If you re-measure all the features after rotation, does it change anything ? (particulary if you level on the top plane after rotation - just to check, I understand you cannot do it on a lot of parts !!!!!)

I think you should post the code (even if it's in french), or a picture of the fixturing

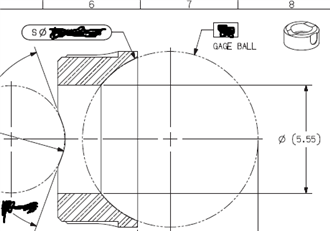

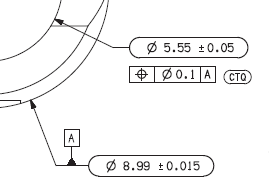

LOADPROBE/PROBE1 TIP/T1A0B0, SHANKIJK=0, 0, 1, ANGLE=0 RECALL/ALIGNMENT,EXTERNAL,APS-PDEA-103722425_A MODE/DCC PREHIT/1.5 RETRACT/1.5 CLEARP/ZPLUS,200,ZPLUS,0,OFF MOVE/CLEARPLANE MOVE/POINT,NORMAL,<0,0,200> CER1 =FEAT/CONTACT/CIRCLE/DEFAULT,CARTESIAN,IN,LEAST_SQR THEO/<0,0,-2>,<0,0,1>,5.55 ACTL/<-0.6152,-0.271,-2>,<0,0,1>,5.5548 TARG/<0,0,-2>,<0,0,1> START ANG=0,END ANG=360 ANGLE VEC=<0,-1,0> DIRECTION=CW SHOW FEATURE PARAMETERS=NO SHOW CONTACT PARAMETERS=NO CLEARP/ZPLUS,5,ZPLUS,0,ON A1 =ALIGNMENT/START,RECALL:APS-PDEA-103722425_A,LIST=YES ALIGNMENT/TRANS,XAXIS,CER1 ALIGNMENT/TRANS,YAXIS,CER1 ALIGNMENT/END MOVE/CLEARPLANE CER2 =FEAT/CONTACT/CIRCLE/DEFAULT,CARTESIAN,OUT,LEAST_SQR THEO/<0,0,-0.5>,<0,0,1>,8.99,0 ACTL/<-0.0008,0.0641,-0.5>,<0,0,1>,8.9976,0 TARG/<0,0,-0.5>,<0,0,1> START ANG=180,END ANG=540 ANGLE VEC=<0,-1,0> DIRECTION=CW SHOW FEATURE PARAMETERS=YES VOID DETECTION=NO REMEASURE=NO SURFACE=THICKNESS_NONE,0 MEASURE MODE=NOMINALS RMEAS=NONE,NONE,NONE CIRCULAR MOVES=CIRCULAR GRAPHICAL ANALYSIS=NO FEATURE LOCATOR=NO,NO,"" SHOW CONTACT PARAMETERS=YES NUMHITS=7,DEPTH=0,PITCH=0 SAMPLE METHOD=SAMPLE_HITS SAMPLE HITS=0,SPACER=0 AVOIDANCE MOVE=NO,DISTANCE=10 FIND HOLE=DISABLED,ONERROR=NO,READ POS=NO SHOW HITS=NO ASSIGN/V1=CER2.R-0.20 MOVE/CLEARPLANE PNT1 =FEAT/CONTACT/VECTOR POINT/DEFAULT,POLAR THEO/<V1,90,0>,<0,0,1> ACTL/<4.2989,89.9965,0.3247>,<0,0,1> TARG/<V1,90,0>,<0,0,1> SNAP=NO SHOW FEATURE PARAMETERS=YES SURFACE=THICKNESS_NONE,0 MEASURE MODE=NOMINALS RMEAS=NONE,NONE,NONE GRAPHICAL ANALYSIS=NO FEATURE LOCATOR=NO,NO,"" SHOW CONTACT PARAMETERS=YES AVOIDANCE MOVE=NO,DISTANCE=10 SHOW HITS=NO A4 =ALIGNMENT/START,RECALL:A1,LIST=YES ALIGNMENT/TRANS,ZAXIS,PNT1 ALIGNMENT/END PLN1 =FEAT/CONTACT/PLANE/DEFAULT,CARTESIAN,TRIANGLE,LEAST_SQR THEO/<0,0,0>,<0,0,1> ACTL/<-0.0004,-0.019,0.1625>,<-0.0037827,0.0390827,0.9992288> TARG/<0,0,0>,<0,0,1> ANGLE VEC=<0,-1,0>,RADIAL SHOW FEATURE PARAMETERS=NO SHOW CONTACT PARAMETERS=YES NUMHITS=7,NUMROWS=1 SPACER=V1 AVOIDANCE MOVE=NO,DISTANCE=2 SHOW HITS=NO DIM PLAT1= FLATNESS OF PLANE PLN1 UNITS=MM ,$ GRAPH=OFF TEXT=OFF MULT=100.00 ARROWDENSITY=100 OUTPUT=BOTH AX NOMINAL +TOL -TOL MEAS DEV OUTTOL M 0.0000 0.0150 0.0000 0.0195 0.0195 0.0045 > A2 =ALIGNMENT/START,RECALL:A1,LIST=YES ALIGNMENT/LEVEL,ZPLUS,PLN1 ALIGNMENT/TRANS,XAXIS,CER2 ALIGNMENT/TRANS,YAXIS,CER2 ALIGNMENT/TRANS,ZAXIS,PLN1 ALIGNMENT/END MOVE/CLEARPLANE CER8_99 =FEAT/CONTACT/CIRCLE/DEFAULT,CARTESIAN,OUT,LEAST_SQR THEO/<0,0,-0.5>,<0,0,1>,8.99,0 ACTL/<-0.0003,-0.0014,-0.5>,<0,0,1>,8.9912,0 TARG/<0,0,-0.5>,<0,0,1> START ANG=-90,END ANG=270 ANGLE VEC=<0,-1,0> DIRECTION=CW SHOW FEATURE PARAMETERS=NO SHOW CONTACT PARAMETERS=YES NUMHITS=23,DEPTH=0,PITCH=0 SAMPLE METHOD=SAMPLE_HITS SAMPLE HITS=0,SPACER=0 AVOIDANCE MOVE=NO,DISTANCE=10 FIND HOLE=DISABLED,ONERROR=NO,READ POS=NO SHOW HITS=NO A3 =ALIGNMENT/START,RECALL:A2,LIST=YES ALIGNMENT/TRANS,XAXIS,CER8_99 ALIGNMENT/TRANS,YAXIS,CER8_99 ALIGNMENT/END MOVE/CLEARPLANE CER5_55MI =FEAT/CONTACT/CIRCLE/DEFAULT,CARTESIAN,IN,MAX_INSC THEO/<0,0,-3>,<0,0,1>,5.55 ACTL/<-0.0056,0.0004,-3>,<0,0,1>,5.544 TARG/<0,0,-3>,<0,0,1> START ANG=0,END ANG=360 ANGLE VEC=<0,-1,0> DIRECTION=CW SHOW FEATURE PARAMETERS=NO SHOW CONTACT PARAMETERS=YES NUMHITS=17,DEPTH=0,PITCH=0 SAMPLE METHOD=SAMPLE_HITS SAMPLE HITS=0,SPACER=0 AVOIDANCE MOVE=NO,DISTANCE=10 FIND HOLE=DISABLED,ONERROR=NO,READ POS=NO SHOW HITS=NO SCN1 =FEAT/SET,CARTESIAN THEO/<0,0,-3>,<0,0,1> ACTL/<-0.0024,0.0008,-2.9992>,<0,0,1> CONSTR/SET,BASIC,CER5_55MI.HIT[1..CER5_55MI.NUMHITS],, CER5_55LS =FEAT/CIRCLE,CARTESIAN,IN,LEAST_SQR,NO THEO/<0,0,-3>,<0,0,1>,5.55 ACTL/<-0.005,0.0017,-2.9992>,<0,0,1>,5.5525 CONSTR/CIRCLE,BF,2D,SCN1,, OUTLIER_REMOVAL/OFF,3 FILTER/OFF,UPR=0 MOVE/CLEARPLANE

DIM LOC1= LOCATION OF CIRCLE CER8_99 UNITS=MM ,$ GRAPH=OFF TEXT=OFF MULT=10.00 OUTPUT=BOTH HALF ANGLE=NO AX NOMINAL +TOL -TOL MEAS DEV OUTTOL D 8.9900 0.0150 -0.0150 8.9912 0.0012 0.0000 # RN 0.0000 0.0300 0.0000 0.0044 0.0044 0.0000 # END OF DIMENSION LOC1 DIM LOC2= LOCATION OF CIRCLE CER5_55MI UNITS=MM ,$ GRAPH=OFF TEXT=OFF MULT=10.00 OUTPUT=BOTH HALF ANGLE=NO AX NOMINAL +TOL -TOL MEAS DEV OUTTOL D 5.5500 0.0500 -0.0500 5.5440 -0.0060 0.0000 # RN 0.0000 0.1000 0.0000 0.0111 0.0111 0.0000 # END OF DIMENSION LOC2 DIM LOC3= POSITION OF CIRCLE CER5_55LS UNITS=MM ,$ GRAPH=OFF TEXT=OFF MULT=10.00 OUTPUT=BOTH FIT TO DATUMS=OFF DEV PERPEN CENTERLINE=OFF DISPLAY=DIAMETER AX NOMINAL +TOL -TOL BONUS MEAS DEV OUTTOL X 0.0000 -0.0050 -0.0050 Y 0.0000 0.0017 0.0017 TP RFS 0.1000 0.0000 0.0106 0.0106 0.0000 # END OF DIMENSION LOC3

I just purposed to lock the rotation trying to explain the defects. If you re-measure all the features after rotation, does it change anything ? (particulary if you level on the top plane after rotation - just to check, I understand you cannot do it on a lot of parts !!!!!)

I think you should post the code (even if it's in french), or a picture of the fixturing

LOADPROBE/PROBE1 TIP/T1A0B0, SHANKIJK=0, 0, 1, ANGLE=0 RECALL/ALIGNMENT,EXTERNAL,APS-PDEA-103722425_A MODE/DCC PREHIT/1.5 RETRACT/1.5 CLEARP/ZPLUS,200,ZPLUS,0,OFF MOVE/CLEARPLANE MOVE/POINT,NORMAL,<0,0,200> CER1 =FEAT/CONTACT/CIRCLE/DEFAULT,CARTESIAN,IN,LEAST_SQR THEO/<0,0,-2>,<0,0,1>,5.55 ACTL/<-0.6152,-0.271,-2>,<0,0,1>,5.5548 TARG/<0,0,-2>,<0,0,1> START ANG=0,END ANG=360 ANGLE VEC=<0,-1,0> DIRECTION=CW SHOW FEATURE PARAMETERS=NO SHOW CONTACT PARAMETERS=NO CLEARP/ZPLUS,5,ZPLUS,0,ON A1 =ALIGNMENT/START,RECALL:APS-PDEA-103722425_A,LIST=YES ALIGNMENT/TRANS,XAXIS,CER1 ALIGNMENT/TRANS,YAXIS,CER1 ALIGNMENT/END MOVE/CLEARPLANE CER2 =FEAT/CONTACT/CIRCLE/DEFAULT,CARTESIAN,OUT,LEAST_SQR THEO/<0,0,-0.5>,<0,0,1>,8.99,0 ACTL/<-0.0008,0.0641,-0.5>,<0,0,1>,8.9976,0 TARG/<0,0,-0.5>,<0,0,1> START ANG=180,END ANG=540 ANGLE VEC=<0,-1,0> DIRECTION=CW SHOW FEATURE PARAMETERS=YES VOID DETECTION=NO REMEASURE=NO SURFACE=THICKNESS_NONE,0 MEASURE MODE=NOMINALS RMEAS=NONE,NONE,NONE CIRCULAR MOVES=CIRCULAR GRAPHICAL ANALYSIS=NO FEATURE LOCATOR=NO,NO,"" SHOW CONTACT PARAMETERS=YES NUMHITS=7,DEPTH=0,PITCH=0 SAMPLE METHOD=SAMPLE_HITS SAMPLE HITS=0,SPACER=0 AVOIDANCE MOVE=NO,DISTANCE=10 FIND HOLE=DISABLED,ONERROR=NO,READ POS=NO SHOW HITS=NO ASSIGN/V1=CER2.R-0.20 MOVE/CLEARPLANE PNT1 =FEAT/CONTACT/VECTOR POINT/DEFAULT,POLAR THEO/<V1,90,0>,<0,0,1> ACTL/<4.2989,89.9965,0.3247>,<0,0,1> TARG/<V1,90,0>,<0,0,1> SNAP=NO SHOW FEATURE PARAMETERS=YES SURFACE=THICKNESS_NONE,0 MEASURE MODE=NOMINALS RMEAS=NONE,NONE,NONE GRAPHICAL ANALYSIS=NO FEATURE LOCATOR=NO,NO,"" SHOW CONTACT PARAMETERS=YES AVOIDANCE MOVE=NO,DISTANCE=10 SHOW HITS=NO A4 =ALIGNMENT/START,RECALL:A1,LIST=YES ALIGNMENT/TRANS,ZAXIS,PNT1 ALIGNMENT/END PLN1 =FEAT/CONTACT/PLANE/DEFAULT,CARTESIAN,TRIANGLE,LEAST_SQR THEO/<0,0,0>,<0,0,1> ACTL/<-0.0004,-0.019,0.1625>,<-0.0037827,0.0390827,0.9992288> TARG/<0,0,0>,<0,0,1> ANGLE VEC=<0,-1,0>,RADIAL SHOW FEATURE PARAMETERS=NO SHOW CONTACT PARAMETERS=YES NUMHITS=7,NUMROWS=1 SPACER=V1 AVOIDANCE MOVE=NO,DISTANCE=2 SHOW HITS=NO DIM PLAT1= FLATNESS OF PLANE PLN1 UNITS=MM ,$ GRAPH=OFF TEXT=OFF MULT=100.00 ARROWDENSITY=100 OUTPUT=BOTH AX NOMINAL +TOL -TOL MEAS DEV OUTTOL M 0.0000 0.0150 0.0000 0.0195 0.0195 0.0045 > A2 =ALIGNMENT/START,RECALL:A1,LIST=YES ALIGNMENT/LEVEL,ZPLUS,PLN1 ALIGNMENT/TRANS,XAXIS,CER2 ALIGNMENT/TRANS,YAXIS,CER2 ALIGNMENT/TRANS,ZAXIS,PLN1 ALIGNMENT/END MOVE/CLEARPLANE CER8_99 =FEAT/CONTACT/CIRCLE/DEFAULT,CARTESIAN,OUT,LEAST_SQR THEO/<0,0,-0.5>,<0,0,1>,8.99,0 ACTL/<-0.0003,-0.0014,-0.5>,<0,0,1>,8.9912,0 TARG/<0,0,-0.5>,<0,0,1> START ANG=-90,END ANG=270 ANGLE VEC=<0,-1,0> DIRECTION=CW SHOW FEATURE PARAMETERS=NO SHOW CONTACT PARAMETERS=YES NUMHITS=23,DEPTH=0,PITCH=0 SAMPLE METHOD=SAMPLE_HITS SAMPLE HITS=0,SPACER=0 AVOIDANCE MOVE=NO,DISTANCE=10 FIND HOLE=DISABLED,ONERROR=NO,READ POS=NO SHOW HITS=NO A3 =ALIGNMENT/START,RECALL:A2,LIST=YES ALIGNMENT/TRANS,XAXIS,CER8_99 ALIGNMENT/TRANS,YAXIS,CER8_99 ALIGNMENT/END MOVE/CLEARPLANE CER5_55MI =FEAT/CONTACT/CIRCLE/DEFAULT,CARTESIAN,IN,MAX_INSC THEO/<0,0,-3>,<0,0,1>,5.55 ACTL/<-0.0056,0.0004,-3>,<0,0,1>,5.544 TARG/<0,0,-3>,<0,0,1> START ANG=0,END ANG=360 ANGLE VEC=<0,-1,0> DIRECTION=CW SHOW FEATURE PARAMETERS=NO SHOW CONTACT PARAMETERS=YES NUMHITS=17,DEPTH=0,PITCH=0 SAMPLE METHOD=SAMPLE_HITS SAMPLE HITS=0,SPACER=0 AVOIDANCE MOVE=NO,DISTANCE=10 FIND HOLE=DISABLED,ONERROR=NO,READ POS=NO SHOW HITS=NO SCN1 =FEAT/SET,CARTESIAN THEO/<0,0,-3>,<0,0,1> ACTL/<-0.0024,0.0008,-2.9992>,<0,0,1> CONSTR/SET,BASIC,CER5_55MI.HIT[1..CER5_55MI.NUMHITS],, CER5_55LS =FEAT/CIRCLE,CARTESIAN,IN,LEAST_SQR,NO THEO/<0,0,-3>,<0,0,1>,5.55 ACTL/<-0.005,0.0017,-2.9992>,<0,0,1>,5.5525 CONSTR/CIRCLE,BF,2D,SCN1,, OUTLIER_REMOVAL/OFF,3 FILTER/OFF,UPR=0 MOVE/CLEARPLANE

DIM LOC1= LOCATION OF CIRCLE CER8_99 UNITS=MM ,$ GRAPH=OFF TEXT=OFF MULT=10.00 OUTPUT=BOTH HALF ANGLE=NO AX NOMINAL +TOL -TOL MEAS DEV OUTTOL D 8.9900 0.0150 -0.0150 8.9912 0.0012 0.0000 # RN 0.0000 0.0300 0.0000 0.0044 0.0044 0.0000 # END OF DIMENSION LOC1 DIM LOC2= LOCATION OF CIRCLE CER5_55MI UNITS=MM ,$ GRAPH=OFF TEXT=OFF MULT=10.00 OUTPUT=BOTH HALF ANGLE=NO AX NOMINAL +TOL -TOL MEAS DEV OUTTOL D 5.5500 0.0500 -0.0500 5.5440 -0.0060 0.0000 # RN 0.0000 0.1000 0.0000 0.0111 0.0111 0.0000 # END OF DIMENSION LOC2 DIM LOC3= POSITION OF CIRCLE CER5_55LS UNITS=MM ,$ GRAPH=OFF TEXT=OFF MULT=10.00 OUTPUT=BOTH FIT TO DATUMS=OFF DEV PERPEN CENTERLINE=OFF DISPLAY=DIAMETER AX NOMINAL +TOL -TOL BONUS MEAS DEV OUTTOL X 0.0000 -0.0050 -0.0050 Y 0.0000 0.0017 0.0017 TP RFS 0.1000 0.0000 0.0106 0.0106 0.0000 # END OF DIMENSION LOC3

| © 2025 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |