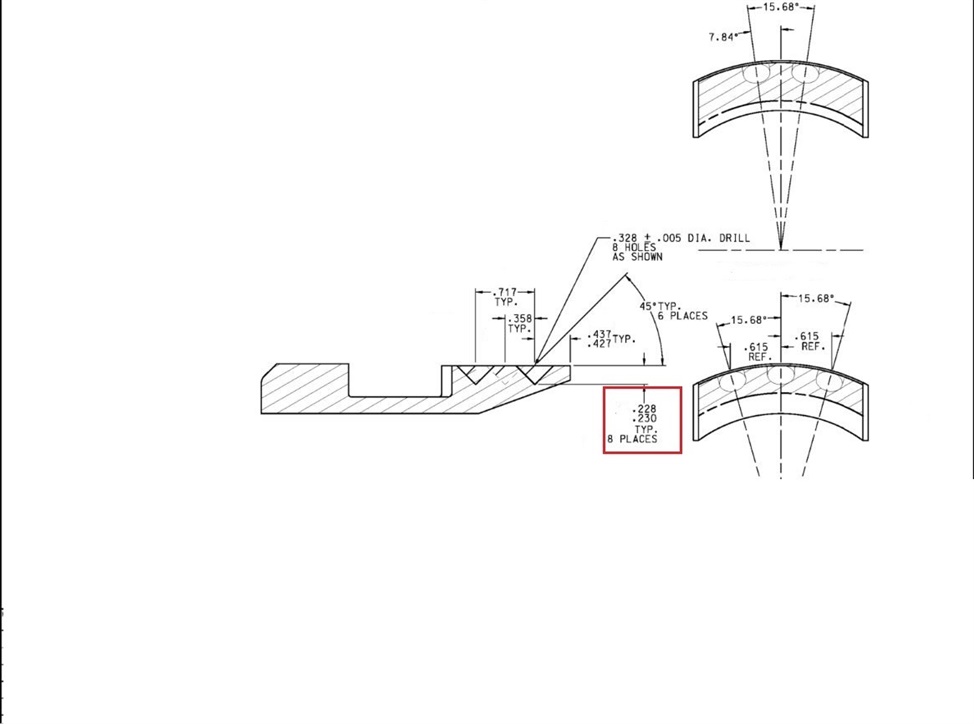

I got this part coming my way soon and am thinking of the best way to measure the depth on the CMM.

its a cylindrical part with the pockets drilled at 45 degrees and split into segments.

I will be receiving these parts split into segments.

I got good results using the comparator since it was able to project the apex, but that isn't going to be efficient for the number of parts i will be receiving.

I can create 2d lines and create the intersection points and measure the depth from that point to the outside diameter.

But i was wondering if there is any way to measure these pockets as a cylinder, and then measure the bottom of the pocket as a plane and find the lowest point which the cylinder and plane intersect?

not sure if that makes sense?

looking for some ideas?

what do you think the best way to measure the depth on these parts is?

Thanks in advance you guys have always been a great help!