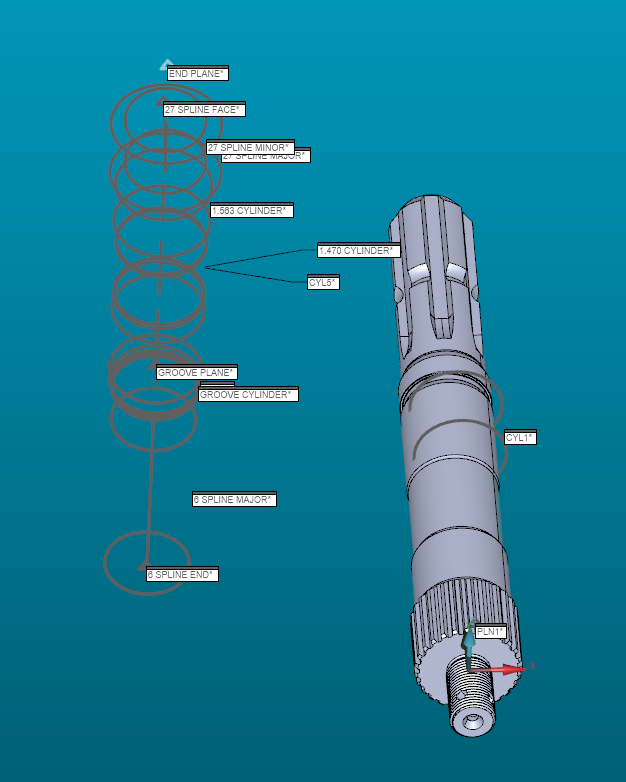

What I've done is programmed all of the features. First a cylinder and plane (for alignment) in manual mode, and the rest of the features dcc mode. When I hit execute I first manually measure the cylinder and plane, then dcc takes over and tries hitting off in space. It seems like its using the pre-programmed coordinates for hits rather than adjusting the dcc hits based on the alignment.