Your Products have been synced, click here to refresh

Your Products have been synced, click here to refresh

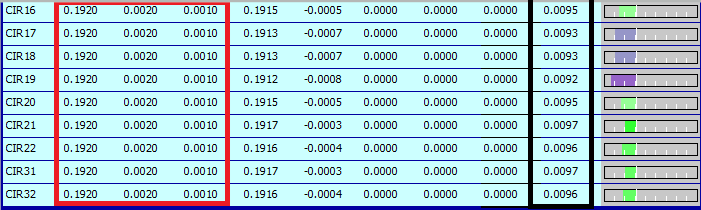

That is why PC-DMIS does not support simultaneous evaluations for lower segments of composite FCFs.This principle does not apply to the lower segments of composite feature control frames. See para. 7.5.4.2. If a simultaneous requirement is desired for the lower segments of two or more composite feature control frames, a notation such as SIM REQT shall be placed adjacent to each applicable lower segment of the feature control frames.

| © 2024 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |