Your Products have been synced, click here to refresh

Your Products have been synced, click here to refresh

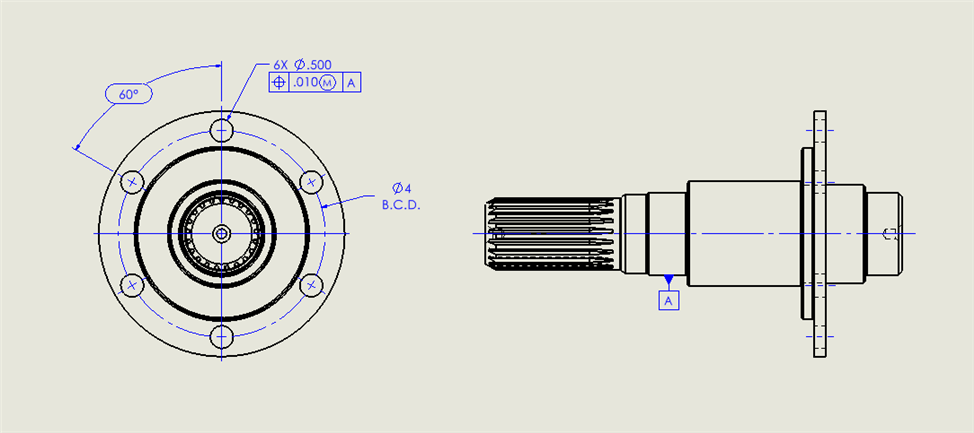

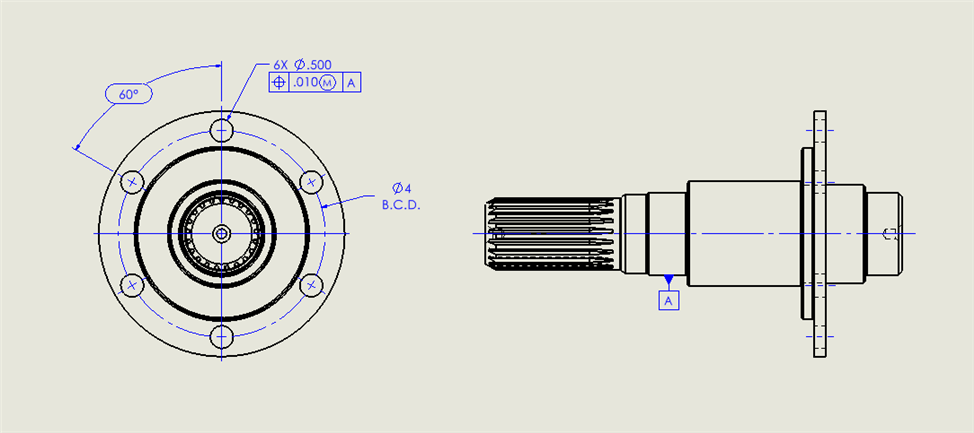

It's essentially the hole pattern to itself.

Probably will have to a manual alignment using two of the bolt holes to offset before going to DCC.

Create a cylinder on Datum A, then level and set the origin on it.

Measure the bolt hole circles and do a 2D best fit rotary alignment. (Terminology may not be correct.)

Then report the position of the bolt hole circles.

| © 2024 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |