Here's my test program with just 2 parts.

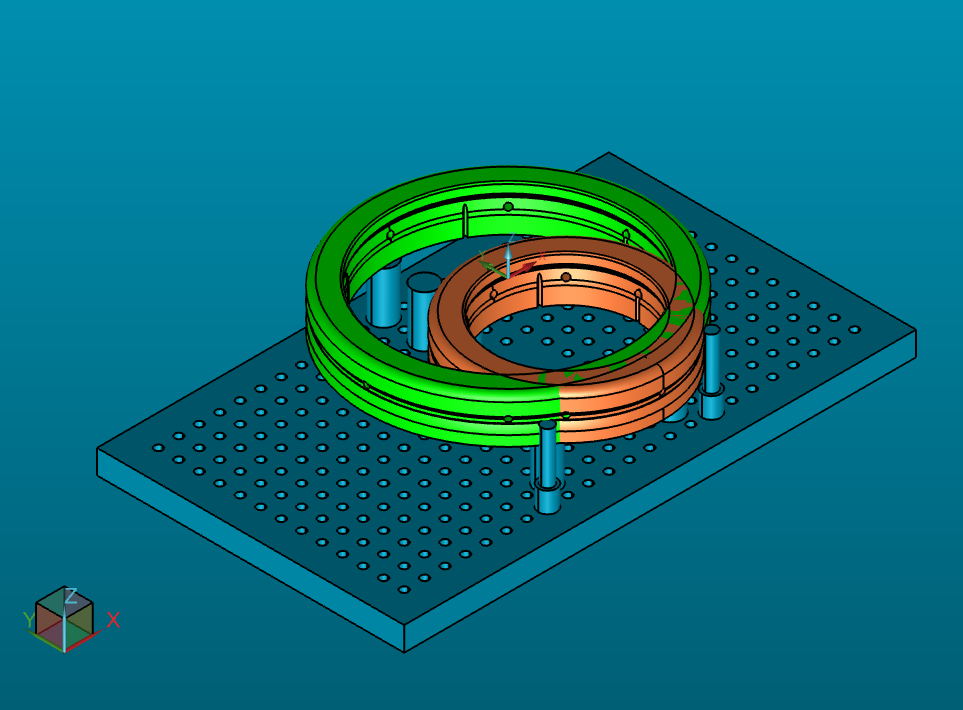

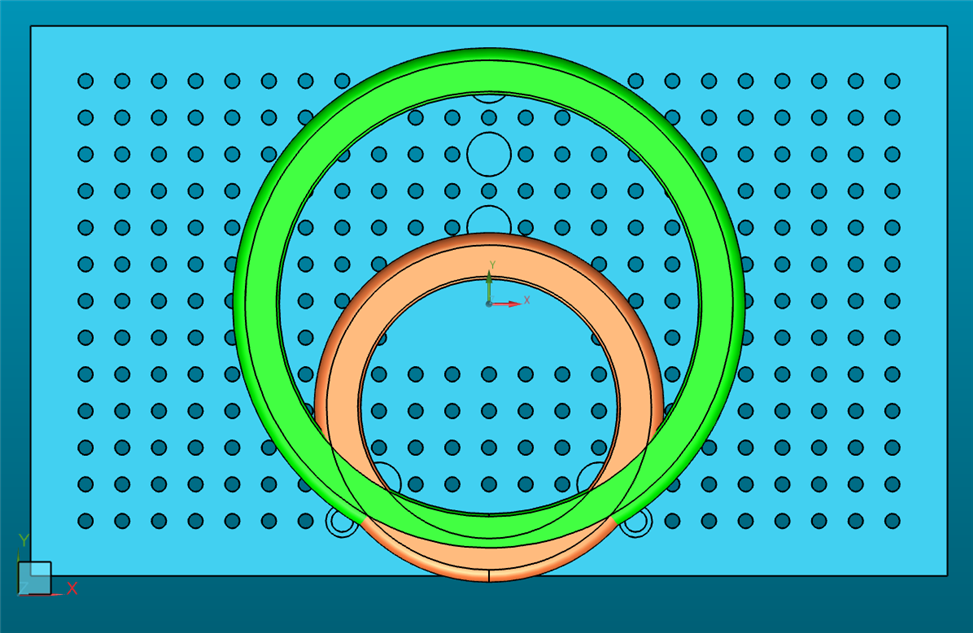

LOADPROBE/6X30 TIP/TIP1, SHANKIJK=0, 0, 1, ANGLE=0 C1 =COMMENT/INPUT,NO,FULL SCREEN=NO, select 1 or 2 SELECT/C1.INPUT CASE/1 COMMENT/OPER,NO,FULL SCREEN=NO,AUTO-CONTINUE=NO, you picked small RECALL/ALIGNMENT,EXTERNAL,TEST_FEC0353_MA ASSIGN/IN_DIA=2.755 ASSIGN/OUT_DIA=3.747 GOTO/L1 END_CASE/ CASE/2 COMMENT/OPER,NO,FULL SCREEN=NO,AUTO-CONTINUE=NO, you picked big RECALL/ALIGNMENT,EXTERNAL,TEST_FEC0357_MA ASSIGN/PLANE_SPACER=2.5 ASSIGN/IN_DIA=4.505 ASSIGN/OUT_DIA=5.497 GOTO/L1 END_CASE/ DEFAULT_CASE/ COMMENT/OPER,NO,FULL SCREEN=NO,AUTO-CONTINUE=NO, wrong choice GOTO/C1 END_DEFAULTCASE/ END_SELECT/ L1 =LABEL/ PLN1 =FEAT/CONTACT/PLANE/DEFAULT,CARTESIAN,NONE,LEAST_SQR THEO/<0,0,0>,<0,0,1> ACTL/<0,0,0>,<0,0,1> TARG/<0,0,0>,<0,0,1> ANGLE VEC=<1,0,0>,RADIAL SHOW FEATURE PARAMETERS=NO SHOW CONTACT PARAMETERS=YES NUMHITS=10,NUMRINGS=1 SPACER=PLANE_SPACER AVOIDANCE MOVE=NO,DISTANCE=0.3937 SHOW HITS=NO CYL1 =FEAT/CONTACT/CYLINDER/DEFAULT,CARTESIAN,IN,LEAST_SQR THEO/<0,0,-0.1876>,<0,0,1>,IN_DIA,-0.1576 ACTL/<0,0,-0.1876>,<0,0,1>,2.755,-0.1576 TARG/<0,0,-0.1876>,<0,0,1> START ANG=0,END ANG=360 ANGLE VEC=<1,0,0> DIRECTION=CCW SHOW FEATURE PARAMETERS=NO SHOW CONTACT PARAMETERS=YES NUMHITS=10,NUMLEVELS=2,DEPTH=0,END OFFSET=0,PITCH=0 SAMPLE METHOD=SAMPLE_HITS SAMPLE HITS=0,SPACER=0 AVOIDANCE MOVE=BOTH,DISTANCE=0.2 FIND HOLE=DISABLED,ONERROR=NO,READ POS=NO SHOW HITS=NO A1 =ALIGNMENT/START,RECALL:USE_ACTIVE_ALIGNMENT(RECALL:TEST_FEC0 357_MA),LIST=YES ALIGNMENT/LEVEL,ZPLUS,PLN1 ALIGNMENT/TRANS,XAXIS,CYL1 ALIGNMENT/TRANS,YAXIS,CYL1 ALIGNMENT/TRANS,ZAXIS,PLN1 ALIGNMENT/END CIR1 =FEAT/CONTACT/CIRCLE/DEFAULT,CARTESIAN,OUT,LEAST_SQR THEO/<0,0,0>,<0,0,1>,OUT_DIA,0 ACTL/<0,0,0>,<0,0,1>,3.747,0 TARG/<0,0,0>,<0,0,1> START ANG=0,END ANG=360 ANGLE VEC=<1,0,0> DIRECTION=CCW SHOW FEATURE PARAMETERS=NO SHOW CONTACT PARAMETERS=YES NUMHITS=20,DEPTH=0,PITCH=0 SAMPLE METHOD=SAMPLE_HITS SAMPLE HITS=0,SPACER=0 AVOIDANCE MOVE=BOTH,DISTANCE=0.5906 FIND HOLE=DISABLED,ONERROR=NO,READ POS=NO SHOW HITS=NO DIM LOC1= LOCATION OF CYLINDER CYL1 UNITS=IN ,$ GRAPH=OFF TEXT=OFF MULT=10.00 OUTPUT=BOTH HALF ANGLE=NO AX NOMINAL +TOL -TOL MEAS DEV OUTTOL D IN_DIA 0.0020 0.0020 2.7550 0.0000 0.0000 ---#---- END OF DIMENSION LOC1 DIM LOC2= LOCATION OF CIRCLE CIR1 UNITS=IN ,$ GRAPH=OFF TEXT=OFF MULT=10.00 OUTPUT=BOTH HALF ANGLE=NO AX NOMINAL +TOL -TOL MEAS DEV OUTTOL D OUT_DIA 0.0020 0.0020 3.7470 0.0000 0.0000 ---#---- END OF DIMENSION LOC2