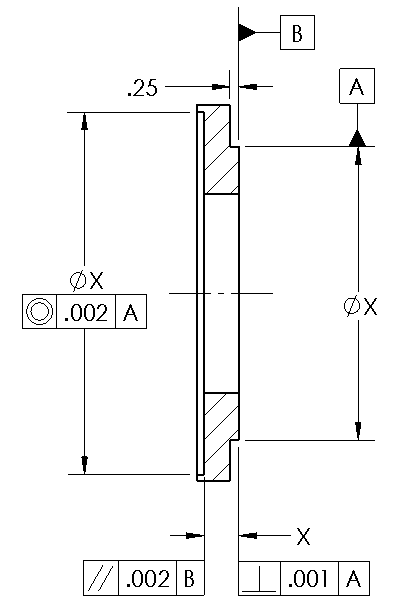

I'm having issues getting good results with the perpendicularity on this part that I'm checking. The drawing is posted.

Reading here on the forum I see that small cylinders could cause issues with perpendicularity. The parallel and concentricity come out great.

I've tried leveling to the datum B plane and the Datum A cylinder without any success.

Basically, if I report the perpendicularity of the cylinder with respect to Datum B I get extremely small numbers such as .00001.

If I report the perpendicularity of the plane with respect to the Datum A cylinder I'm getting measurements ranging from .003-.005.

The range comes from checking different parts but the measurements are consistent for each individual part.

I'm measuring cylinder A with two constructed circles using a 3mm dia stylus. Im using PCDMIS 2022.1.

Any help would be much appreciated. Thanks.