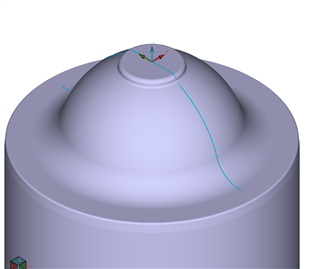

At the moment I use 3 scans to achieve this.

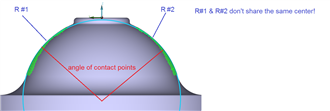

- One scan to evaluate the radius #1 (just the left side)

- One scan to evaluate the radius #2 (just the right side)

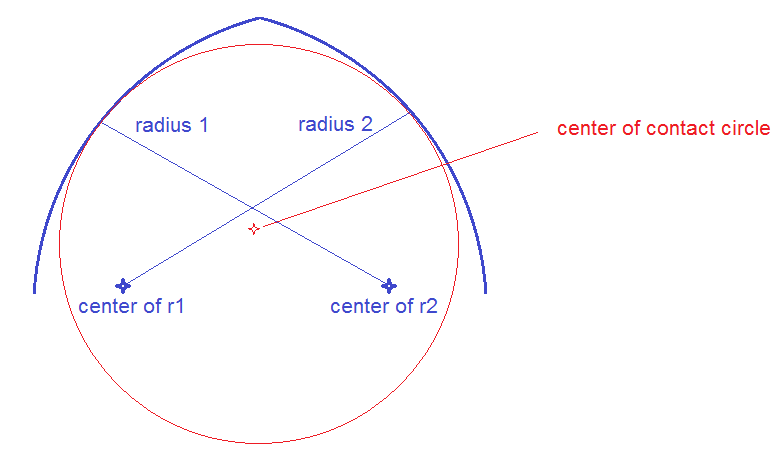

- One scan from left to right (over the top surface) to generate a contact circle which contacts a point left and right each to calculate the contact angle. I use the function "scan minimum" to create the contact circle.

One problem I have, is that the scans are a bit rough/jittery. This results in the contact angle not being very stable.

What I want to do now is the following:

- get rid of the third scan from left to right

- filter the two separate radius scans

- generate the contact circle from the two filtered scans

The problem is, that the feature "scan minimum" doesn't allow me to input 2 separate scans.

I tried to generate a a set of the two scans and a point cloud to get around this limitation but nothing works.

Does somebody knows a way to get around this limitation? Maybe there is a way to feed all the pints into one scan?

If possible I would prefer a solution without a script but if necessary I would also resort to a script.