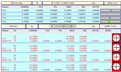

I have a problem with TP. The position of the cylinders on the cone is at an angle. I need to understand why TP is out of tolerance if the diameter and position of these cylinders are correct.

Every tip is valuable.

-A- -> TOP PLN ( Z+ )

-B- ->ID CYL in center ( Z+ )

-C- -> cylinder on the side ( Y-)

Attached Files