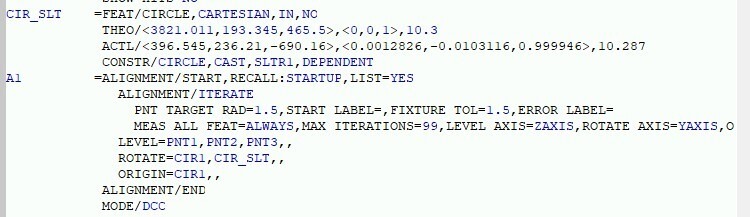

I am evaluating programs from our supplier now. One program with Plane Circle round slot datums starts with iterate alignment. I wonder whether this is old style start since It takes at least 5 mins on manual hits before running DCC.

Attached Files