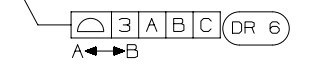

I have a surface profile call out for 3 mm, the program uses 1.5 -1.5 and deviation 3.0 to check all those hits. My question is whether unilateral profile should be only about max min deviation about 3 mm?

Can I use 3 mm and -3 mm to check the hits M value and relays on deviation only?

Thank you

Attached Files