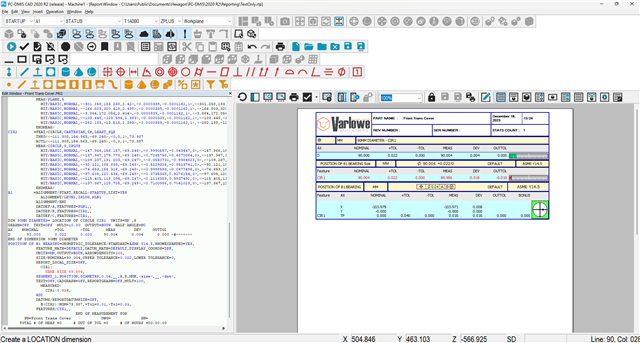

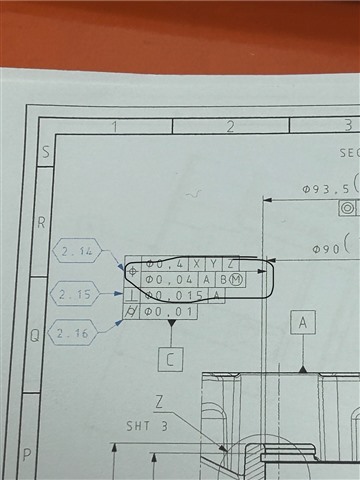

Hello this is going to be a stupid question but im new to CMMing, on my drawing ive been given a positional tolerance of .04mm of a bore with 2 datums, 1 being a different bore and another being the top face of the part, the size of the bore is correct when i measure it with location dimension but when i measure it with the position dimension its saying it is undersize, i dont quite understand where the other numbers are coming from in the box underneath, thank you

Your Products have been synced, click here to refresh