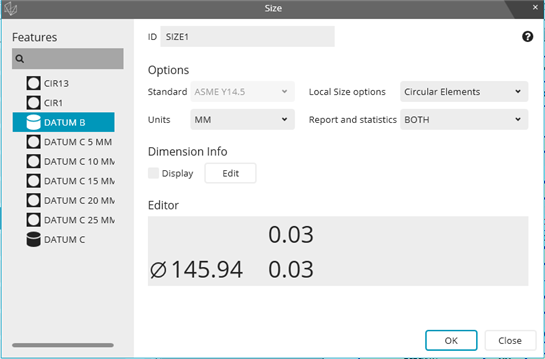

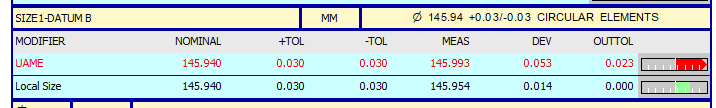

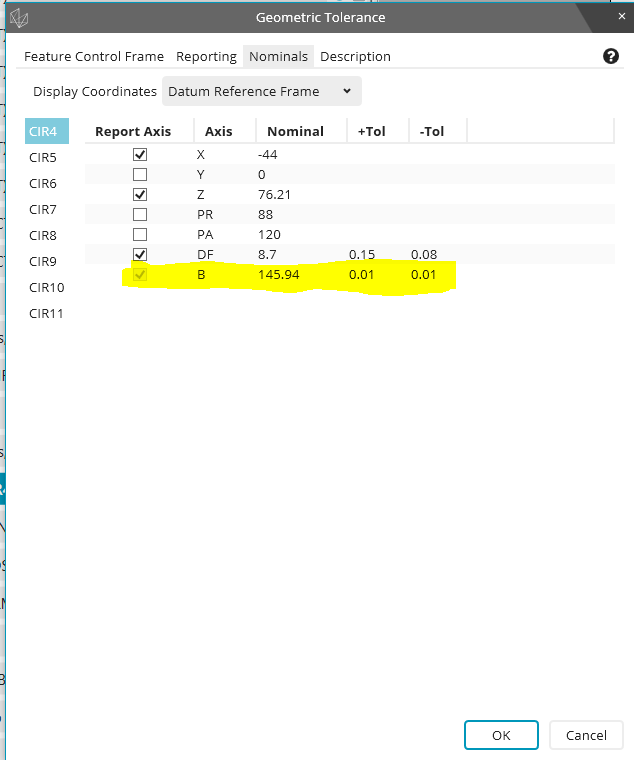

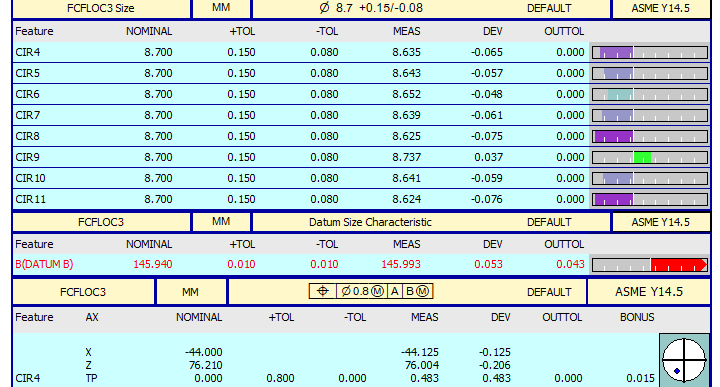

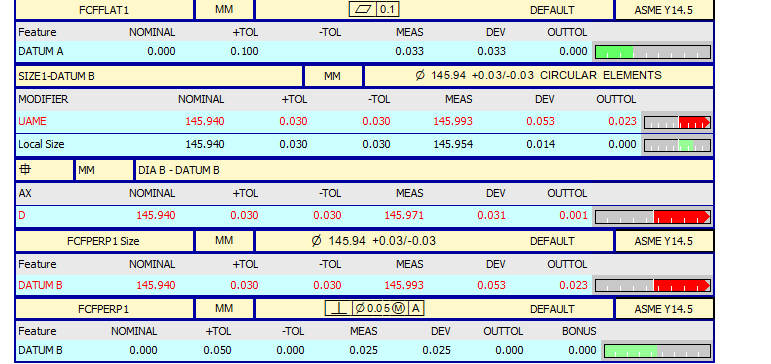

As I understand it, if you want to apply a MMB modifier to a datum in a FCF, you must first ensure that said datum has already been dimensioned with tolerances to determine its MMC and LMC. So my question is, does it need to be dimensioned with a size dimension and default math, or will a location dimension with LSQ math also work? And if you happen to have both in your routine (with the same tolerances applied), will that mess up the position calculation?

Your Products have been synced, click here to refresh