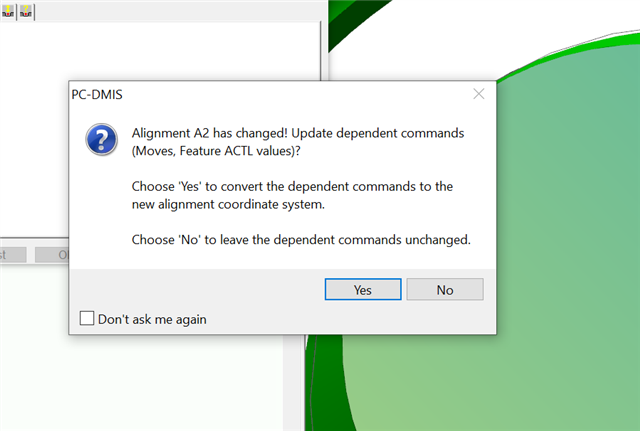

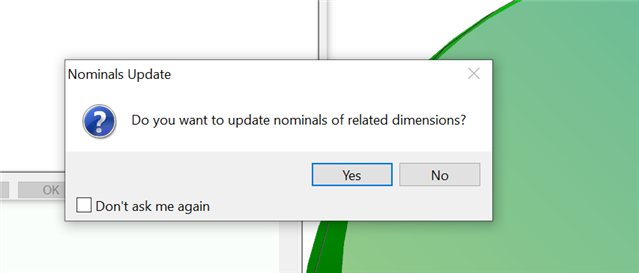

I have been through training and I am still confused on how to use this. After I alter an alignment for example it will ask me if I want to update noms. I always click no because from experience I found it overrides previously programmed nominals. On the other hand I updated an existing program to a new datum scheme, the part had an all over profile that checked bad in the new alignment until I literally re-created the entire profile in the program and now I am wondering if clicking "yes" to update nominals of related dimensions after I changed the alignment would have resolved this.

So when do I click yes or no to "Do you want to update nominals of related...?"