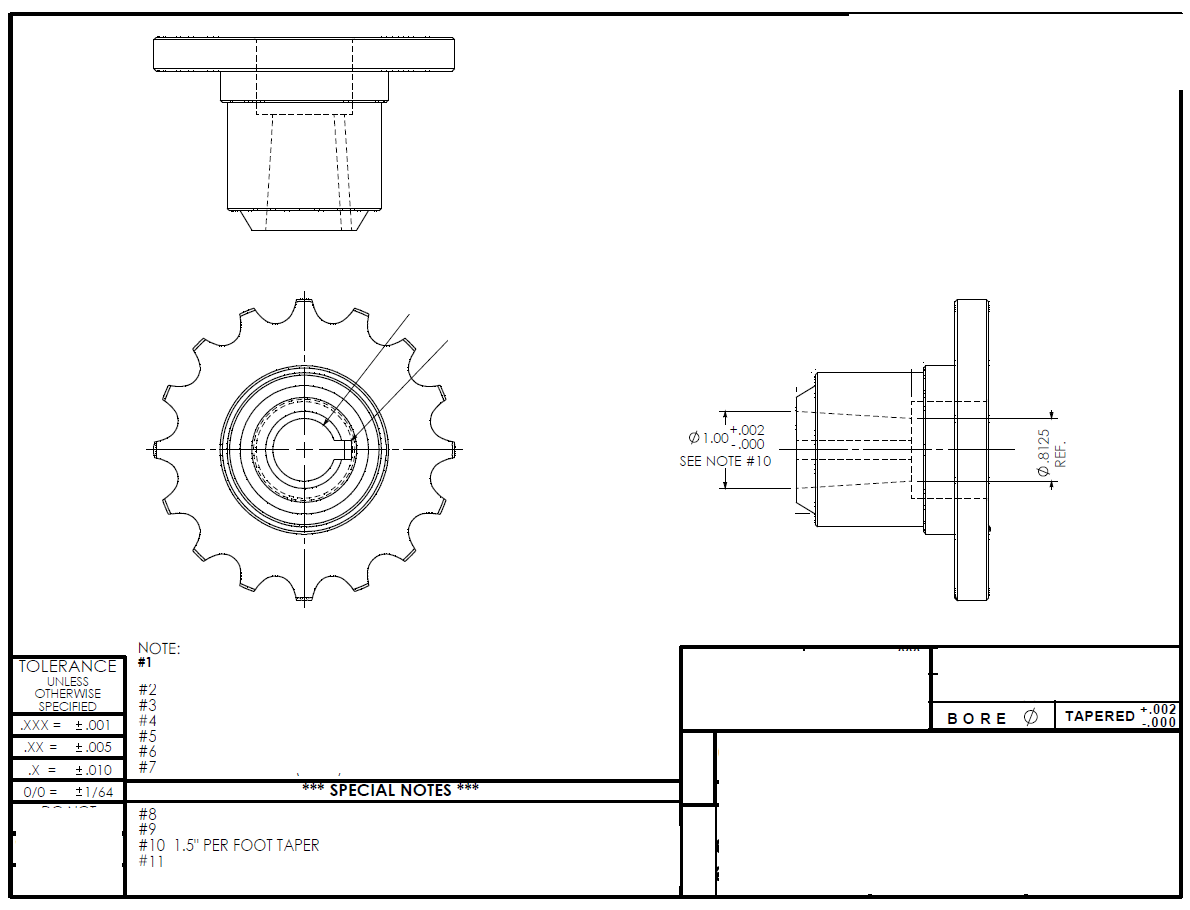

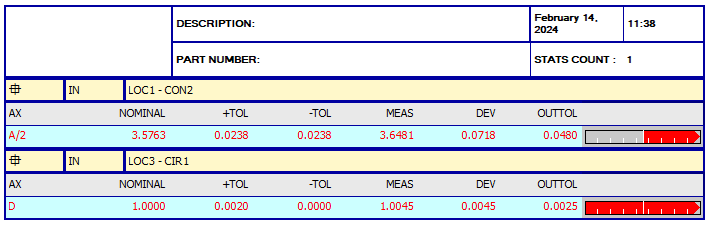

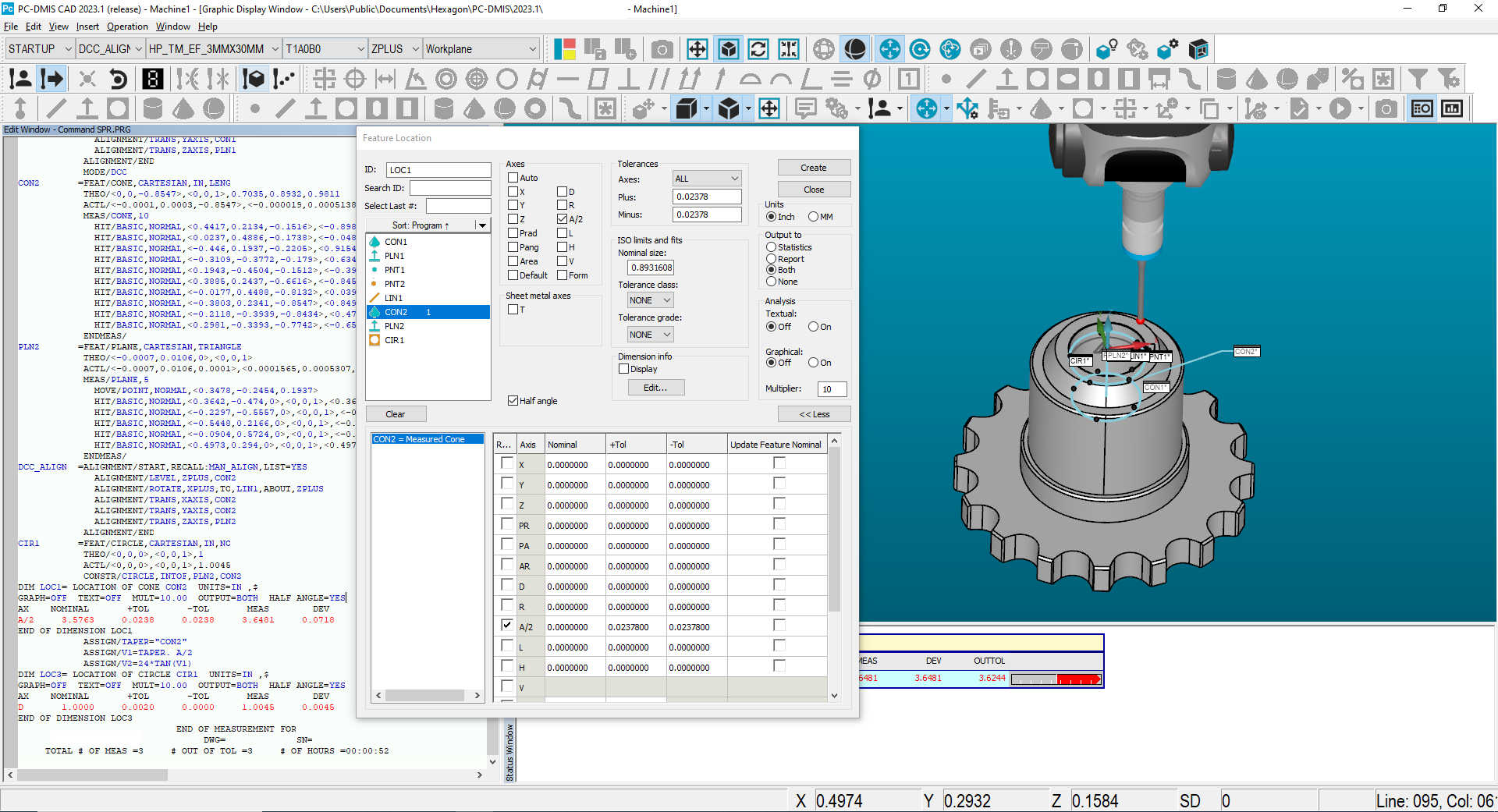

Hey guys. I am inspecting a part with a tapered bore. The drawing calls out '1.5" PER FOOT TAPER' with a tolerance block tolerance of ±.010. I measured the feature as a cone and my options are to report as an angle or half angle. I know that the half angle should be 3.5763. And to translate that to taper per foot I worked out the following equation: taper/foot = 24*tan(half angle). How can I implement this so that my report shows the measured taper/foot with a nominal of 1.500 ±.010? Currently I am reporting the half angle with a tolerance of ±.0238 which is what I calculated as .010"/foot taper as a half angle. Appreciate the help.