Hello all

Hello all

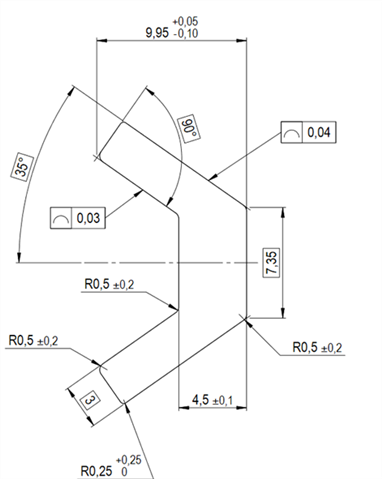

i have these profile bars (about 2.2meters long), and this is how the profile looks.

It also has a straightness callout along the entire length

I need to measure em and i know how to measure profile, i basicailly just do a bunch of vectorpoints, construct a scan set and evaluate profile.

For the straightness i guess i just measure a line across the entire lenght and evaluate straightness

But i dont really know how to align the part. Ive taken a primary plane on the end face of the bar and then measure a line and offset angle 35.

But the ends of the bar are cut raw, and they re not really good feature to use for alignment.

How would i go about to align this part to evalute the staightness n profile?

TY ALL <3