Hey all,

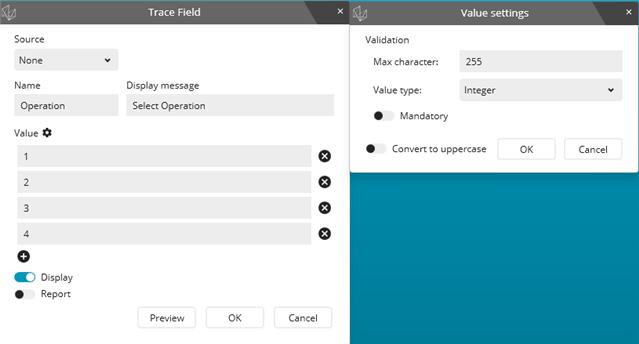

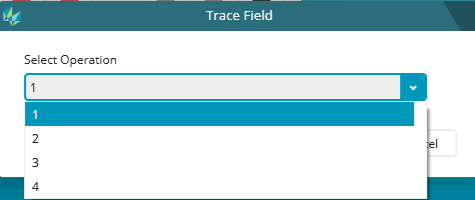

A program begins with a basic alignment and then a DCC alignment. When the program starts it asks what op you're checking, 1, 2, or 3 for example. Depending on what you select the program should construct your alignments and then move on to that op. If you're only checking op2 for example, how do you first instruct pcdmis to run the alignment code before moving on to op2?

It's been years since I've done this and I feel like Forrest Gump all of a sudden.

Thank You