Good morning,

I am new to PC-DMIS and CMM's in general so any tips and information would be greatly appreciated.

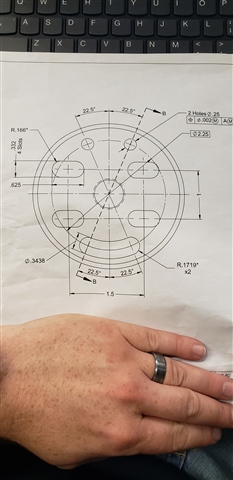

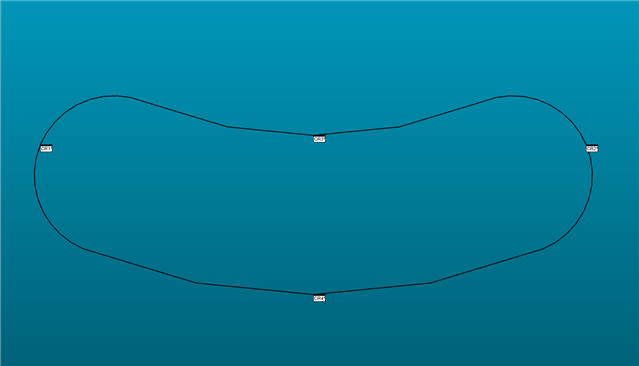

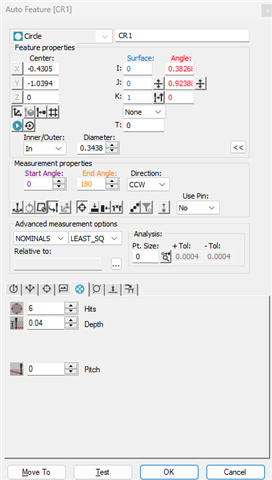

My current issue is trying to program this round slot on an arc.

I will attach a portion of the print, also I don't have a CAD model just part and print.

Thanks to all who help out with this.