The only "Training" I've received was 02/21-24/2021 approximately 2 1/2 days on a manual machine on PCDMIS-2019 I I'm thine only operator on any shift. we upgraded to a GLOBAL S GREEN 7,5,7 this past December. and apart from first shot/last shots involving bolt circle patterns at most. so I've got list experience I this field so please have patience with me if we interact and I ask the same cmm 101 questions a few times or ask for another explanation because I was kinda of just stuck in this position I didn't necessarily ask for it. so thanks in advance.

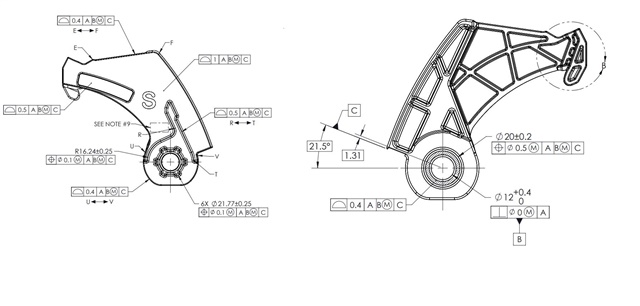

my question has to do with alignments for matching the actual part to cmm along with the print. I'm frustrationg myself because it not clicking with me yet. can someone plz explain how the part should be measured to match part with print call outs. I currently have the side with the letter S for starboard facing the -Y affixed and standing in the Z+ direction I can take a Pic of my set up if necessary. all I've done is a manual alignment using what I believe are the primary secondary and tertiary datums

({PLN_A w/-Y vector},[CYL_B along the Y axis], & {PLN_C -Z vector w/ 21.5 rotation offset })