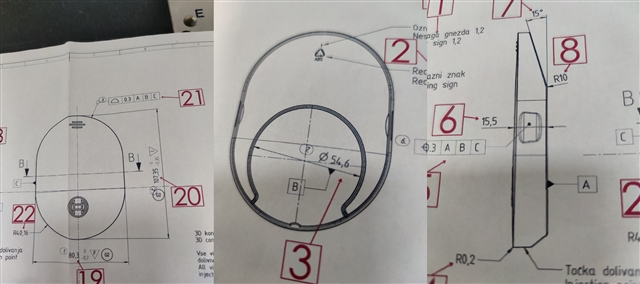

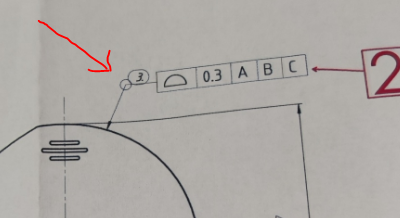

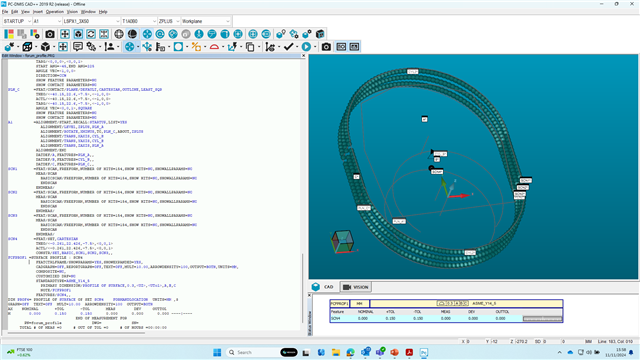

Hello guys, I would need a bit of help as I'm trying to measure this profile of surface dimension. I've been using Hexagon Performance 7.10.7 CMM machine for about 5 months, but this is the first project in which I need to measure profile of surface depended on three datum sufaces A/B/C. For datum A, I tried taking the line of surface, than making a plane, but it always shows me that axis on datum A and datum C are parallel or coincident. Datum B is I assume the circle which I scan and than make constructed circle. For the measurement I scan the radius and use that scan to get profile of surface.

Can you help me on how to take datums A,B,C and is it correct to scan the radius and use it for my dimension.