Hello guys,

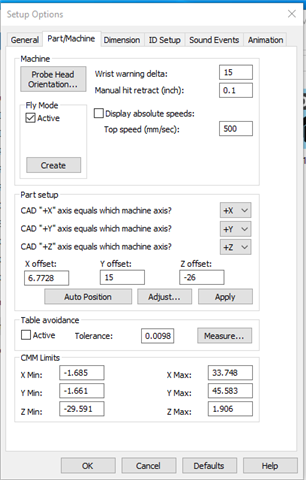

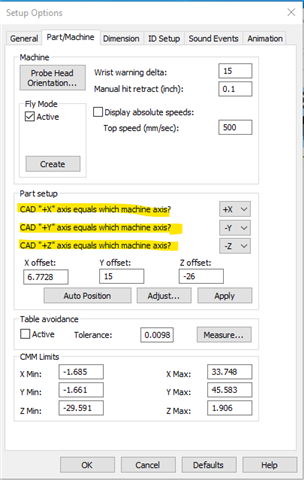

This is the first time I'm importing CAD file into PCDMIS 2018 r2 and I have to check dimensions of part on machine to see if they are in tolerance. After I import my CAD file, how do I align it with the part that is on the machine so I can do the measurements? What is the best strategy?