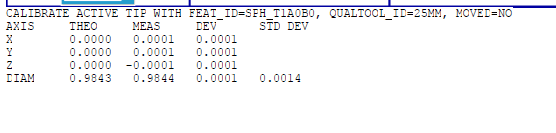

Is a .0014 STD DEV normal?

we are trying to measure diameters and they are reporting +.005 oversize. Could this have to do with our STD DEV being so high?

Your Products have been synced, click here to refresh

Is a .0014 STD DEV normal?

we are trying to measure diameters and they are reporting +.005 oversize. Could this have to do with our STD DEV being so high?

That depends on the hardware you're using - stylus, tip, length, material, module, tactile, scanner. Also, depends on if your example is in metric or inches.

Can you provide more info?

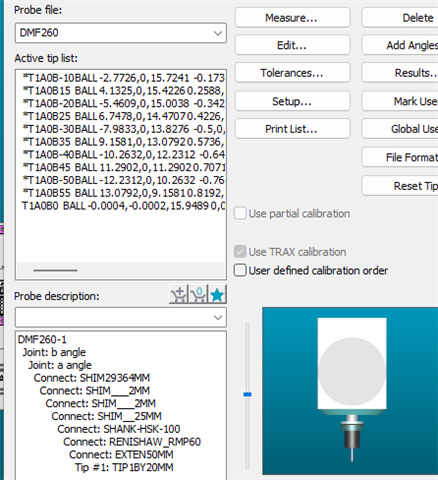

Sure! we are using NC Server 2022.2. Ill take a picture of our probe build which was set up by an applications engineer and looks alot different than what we actually have set up... but according to apps engineer, its correct. I am working in inchs.

dmg mori powerprobe 60 optical

I'm not as familiar with the NC side of things, or the specific probe you're using. Are you measuring with the optical, or the touch probe?

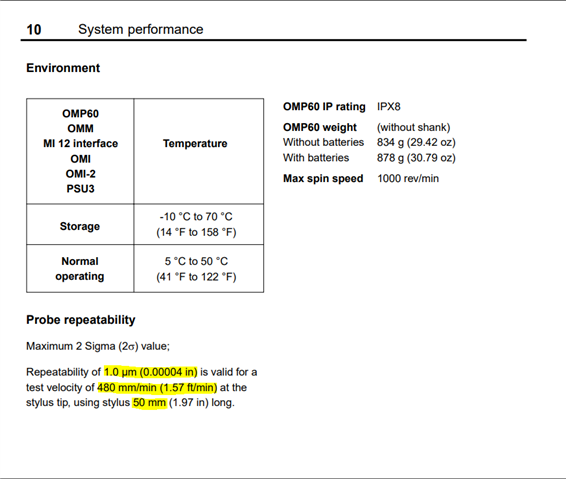

if its the touch probe, then this is what I found in the OMP60 manual about repeatability -

So you should be getting STD DEV closer to that number, depending on actual probe build. Also I would suggest looking into the probe build file that you showed, as its always going to be suggested (and more accurate) to have the probe build match your hardware. (again, I'm not familiar with NC, so maybe that file is want you want)

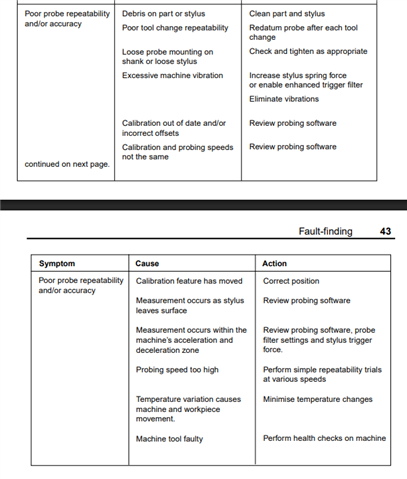

Beyond that, if you're still having high STD DEV, then here is what the OMP60 manual suggests -

hope that helps! good luck

He's in a CNC machine so it's an "optical touch probe" where the optical is just referring to the data transmission type. The probe is held in the spindle and communicates with a receiver via IR signals. Pretty cool stuff.

Thanks! I know I've seen them before, but never learned about them. Good to know though

Thanks! I know I've seen them before, but never learned about them. Good to know though

| © 2025 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |