Your Products have been synced, click here to refresh

Your Products have been synced, click here to refresh

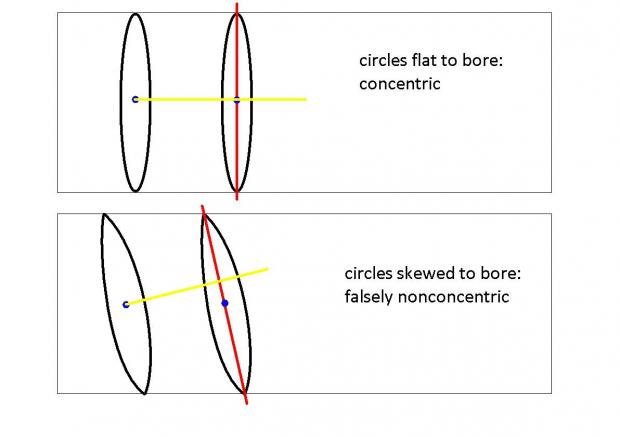

So, I am using a romer arm to measure concentricity of two holes. With a traditional CMM (and different software) we have found the concentricity of the holes to be 0.26mm. However, with the romer arm it shows the concentricity to be 2.9mm. If you take the acuals from the two holes and calculate the concentricity it should read like the traditional CMM???? Why is PC DMIS not giving me the correct reading? Any suggestions on how to measure this dimension with the Romer ARM?

But fear not! Most of the time when the concentricity symbol is placed on a drawing it is used incorrectly and what the designer is really trying to control is position.

So, I am using a romer arm to measure concentricity of two holes. With a traditional CMM (and different software) we have found the concentricity of the holes to be 0.26mm. However, with the romer arm it shows the concentricity to be 2.9mm. If you take the acuals from the two holes and calculate the concentricity it should read like the traditional CMM???? Why is PC DMIS not giving me the correct reading? Any suggestions on how to measure this dimension with the Romer ARM?

You can check concentricity with PCDMIS, BUT it reports it according to ISO standards. That is, it reports concentricity as TP (position).

Lots of luck.

| © 2025 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |