Hope you had a great Christmas and New Year!

I'm writing as I'm seeking metrology advice for products that will quickly go through our aerospace shop.

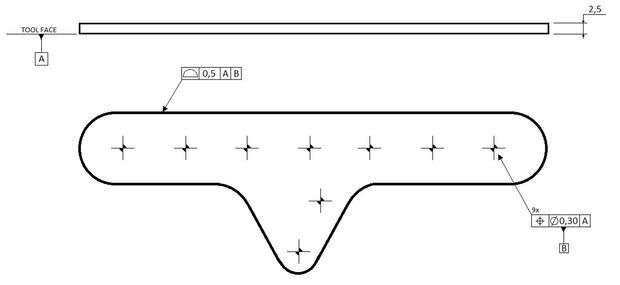

The products are simple, flat, relatively thin composite components. It will be an in-process measurement where only two dimensions need measuring; profile and hole true position.

If you refer to the very rough drawing I've attached. The component's thickness can simply be measured with a vernier.

At the moment I'm thinking of a Romer Arm but I'm wondering if there's anything out there where you can simply throw the component onto a surface and automatically be measured.

Hope I've described what I'm working with well and is understood

Cheers, Ben