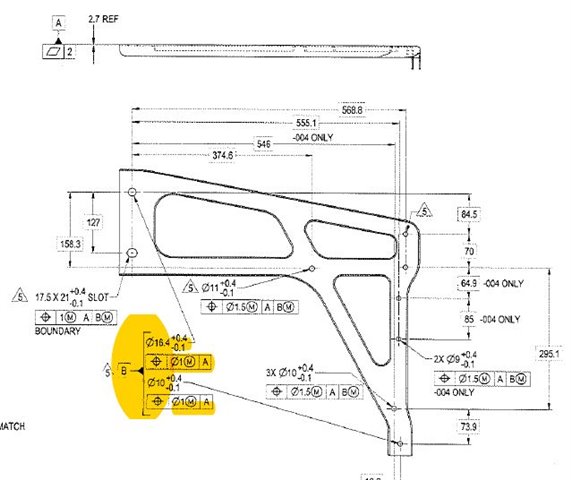

I have been doing GD&T for quite a few years and I am really stumped on what the intent of this call out is. Was hoping someone could share some insight in what the intent is. The are giving me 2 seperate holes to use as Datum B. Typically, i would rotate to these, however, there is no Datum C. That is fine, however they also have a max modifier on datum B in other FCF. How can that be when each hole is a different size and i am only rotating datum B. I think i am missing something here.